The name "led cup light" comes from its shape resembling a cup, with the lamp cup connected to the lamp head and protecting the lamp core. The lamp cup is designed with a parabolic surface and is mainly used for spotlighting, which can effectively reduce light loss.

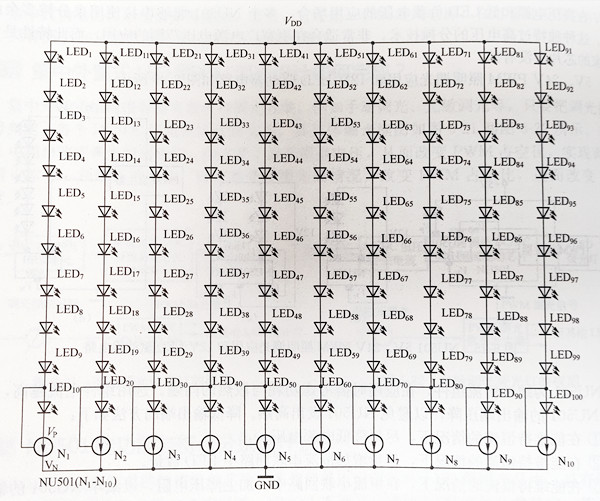

Figure 6-26 shows a 36V DC stable power supply, and NU501 implements a constant current circuit diagram.

Figure 6-26 36V DC regulated power supply, NU501 realizes circuit diagram of constant current circuit

By computer modeling and simulating the spatial structure of the reflector cup light source's light-emitting angle and the reflector cover, tracing the refractive trajectory of light rays, and adjusting the curvature of the reflector cover to achieve the optimal light intensity distribution of the reflector cover and the functional requirements of the lamp cup for various beam angles, the efficiency of the LED reflector cup is greatly improved, reducing the possibility of glare and light scatter, as shown in Figure 6-27. The reflector surface has two effects: orange peel and smooth surface, with high reflectivity, no peeling, and high-temperature resistance.

High-power LED lamp cups use high-brightness white LEDs as light sources, with no light pollution, no harmful chemicals, no fragile glass, and can be directly connected to 220V/110V AC power or 24V/12V DC power. They can also generate various effects such as gradients and jumps through built-in programmable chips. LED lamp cups are widely used in places such as shopping malls, homes, meeting rooms, display cabinets, and advertising lighting, and can also be used as low-power outdoor lighting devices.

Figure 6-27 Shape of led cup light

Low-power LED lamp cups, also known as spotlights, have interfaces such as MR16, E27, GU10, JDRE27, JDRE14, and MR11, etc. They come in various LED quantities such as 12, 15, 18, 21, and 38, with light source diameters of 5mm and 3mm, and emit colors such as white, red, blue, green, and yellow. Applications of low-power LED lamp cups are shown in Figure 6-28.

Figure 6-28 Low-power LED light cup application vision

(1). Various color options are available, such as red, yellow, blue, green, white, tricolor combinations, and colorful variations.

(2). Diverse color-changing modes: When used in conjunction with a controller, the lamp cup can produce various effects, including tricolor synchronous jumping, tricolor synchronous flashing, tricolor synchronous gradient, and tricolor synchronous gradient with jumping.

(3). Varying numbers of LEDs: MR16 lamp cups come in different LED quantities, such as 6, 9, 12, 15, 16, 18, and 20; PAR20 lamp cups have LED quantities of 9, 12, 15, 16, 18, 20, 24, and 38; PAR30 lamp cups have more than 38 LEDs, available in single color or multicolor options.

(4). Long lifespan: The theoretical lifespan of LEDs is up to 100,000 hours, which translates to over 27 years when calculated at 8 hours of daily use.

(5). Low power consumption: Individual LEDs have an average power consumption of 0.05W. In 5mm LED lamp cups, the power consumption varies depending on the number of LEDs: 9 single-color LEDs consume 0.5W, 12 LEDs consume 0.6W, 15 LEDs consume 0.8W, 18 LEDs consume 0.9W, and colorful lamp cups consume 1W.

(6). Minimal heat generation: Single-color lamp cups have low power, resulting in minimal heat generation.

(7). Strong shock resistance: The LEDs in lamp cups are made of high-hardness resin luminescent materials, rather than filament glass, making them more resistant to damage and better adapted to varying environmental temperatures.

(8). Glass-sealed design: Both LED diffusing and single-color lamp cups use transparent (or frosted) glass-sealed designs.

(9). Strong control capabilities: LED lamp cups can be controlled by external controllers to execute various dynamic programs, making them suitable for a wide range of applications, including dynamic pattern design for outdoor billboards and border decoration.

(10). Flexible design: LEDs emit point light, and designers can create various shapes and LED quantities according to customer requirements using point, line, and surface designs, making the design process highly flexible.

Light source color: Red, yellow, white, green, blue, and various color combinations.

Power supply voltage: Available in four standard options - 220V, 110V, 24V, and 12V.

Compatible lamp head specifications: MR16, GU10, JDRE11, JDRE14.

Built-in number of LEDs: Options include 6, 9, 12, 15, and so on.

LED angle: Choices for beam angles typically include 60°, 90°, 120°, and 140° (for diffusing light).

Lens angle: Options for lens angles are typically 30° and 45°.

Brightness: White light typically has a brightness of 1700d/m or above, with varying brightness levels for different colors.

Operating temperature: Should be below 40°C.

Control method: LED constant current drive.

Protection rating: IP43.

Low-power LED lamp cups (spotlights) are made with high-quality toughened glass and offer advantages such as a small size, easy installation, and a wide range of adjustable projection angles.

MR (Multiface Reflect) stands for multi-faceted reflector lamp cup, and the number following MR indicates the lamp cup's diameter (in units of 1/8 inch). For MR16, the diameter is 16 times 1/8 inch, which equals 2 inches or 50mm. MR16 lamp cups have a bi-pin interface. MR16 lamp cups are widely used in decorative lighting for places such as shopping malls, conference halls, KTVs, bars, professional warehouses, and homes.

Common MR16 halogen lamps have power consumption ranging from 10W to 50W, with an output luminous flux of 150 to 800 lumens and an equivalent luminous efficacy of around 15 lm/W. The typical lifespan of halogen lamps is around 2000 hours. Additionally, it's important to avoid significant vibration of the filament in halogen lamps to prevent premature bulb failure.

Using MR16 LED lighting products provides a more cost-effective alternative. For example, using the latest high-brightness LED, such as Philips' LXK2-PWC4-0200, with a color temperature (CCT) of 6500K, it can produce a minimum luminous flux of 200 lm with a 1A drive current. The typical forward voltage of this LED is 3.65V, resulting in a luminous efficacy of 54.79 lm/W (at 1000mA and Tj=150°C). It can be observed that when achieving the same luminous output, LED lamps consume only around 30% of the power compared to halogen lamps. Furthermore, when the LED operates at a junction temperature below 120°C, it can maintain 90% of its luminous output after 50,000 hours of operation.

There are at least 2 billion halogen MR16 lamps in the market, and their widespread use not only consumes a significant amount of electricity but also has adverse environmental impacts, contributing to the greenhouse effect. Additionally, due to the short lifespan of halogen lamps, typically around 400 hours, proper disposal of discarded halogen lamps poses challenges. With increasing demands for energy efficiency and environmental protection, replacing traditional MR16 halogen lamps with MR16 LED lamp cups has become a pressing need. If even 25% of the 2 billion halogen lamps were replaced with LEDs, it would result in a market potential of at least 500 million units. Therefore, many semiconductor companies recognize the immense future market potential of MR16 LED lamps and are introducing driver chips suitable for MR16 LED lamp cups to meet the growing market demand.

There are many brands of driver control chips available for use in MR16 lamp cups, offering a wide range of options. However, understanding the performance characteristics of these driver chips to create more competitive and vibrant products is something that many LED luminaire manufacturers and driver chip designers may not be familiar with. In the current LED lighting market, there is often a gap in knowledge and collaboration between those designing luminaire products and those designing drivers.

The primary basis for choosing driver chips is generally cost-effectiveness. When it comes to the internal switch transistor of the chip, there is a distinction between those with built-in NPN transistors and those with MOSFET transistors (MOSFETs can further be categorized as PMOSFETs and NMOSFETs). A lower on-resistance of the built-in switch transistor results in lower conduction losses. For MR16 LED drivers, which often have limited internal space, it's desirable for the chip to operate at a higher frequency. This allows for the use of smaller inductors and capacitors while also benefiting PCB layout with a smaller chip package size.

The input voltage for MR16 LED lamp cups is typically AC/DC 12V. Using chips designed for a much larger input voltage range (such as LM3402HV or LM3404HV) would be wasteful in this context. After considering all these factors, the price of the chip becomes an important consideration.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China