Solar energy is harnessed through the use of solar panels to convert sunlight into electrical energy, making it an invaluable resource for generating power. Regardless of whether it's a sunny day or cloudy, energy can be collected and stored using solar generators and panels, offering a dependable source of electricity. This "inexhaustible," safe, and environmentally friendly energy source has garnered increasing attention. In this discussion, I will delve into the principles, components, development trends, and practical applications of solar energy, shedding light on its significance.

In a general sense, solar energy refers to the radiant energy emitted by the sun, which modern society primarily utilizes for electricity generation. Ever since the formation of Earth, living organisms have heavily relied on the sun's warmth and light. Throughout history, humans have recognized the utility of sunlight for various purposes, from drying objects to preserving food, such as salt and salted fish. However, as fossil fuel resources dwindle, we are compelled to further explore and develop solar energy. Solar energy utilization can be broadly categorized into two main methods: passive utilization, involving photothermal conversion, and photoelectric conversion.

Solar power represents a burgeoning renewable energy source, with solar energy serving as the foundational energy for various forms on Earth, including wind energy, chemical energy, and the potential energy of water, among others. In a broader context, solar energy originates from the continuous nuclear fusion reactions occurring in sunspots within or on the sun's surface. The average solar radiation intensity in Earth's orbit measures 1367 watts per square meter (W/m²). With Earth's equator spanning 40,000 kilometers, this results in an estimated energy intake of 173,000 terawatts (TW). At sea level, the standard peak intensity is 1 kilowatt per square meter (kW/m²), and the 24-hour annual average radiation intensity at a specific location on Earth's surface is around 0.20 kW/m², equivalent to 102,000 TW of energy. Human existence depends on this energy source, including all other renewable energy forms. However, despite the vast potential, the low energy density of solar energy, its variability by location and time, and other challenges limit its role in the overall energy system.

While the sun's energy radiated into Earth's atmosphere is a mere fraction of its total output (just one-2.2 billionth), it amounts to a staggering 173,000 TW. This means that the sun imparts onto Earth's surface an energy equivalent to five million tons of coal every second. Wind energy, hydropower, ocean temperature differentials, wave energy, biomass energy, and a portion of tidal energy all trace their roots back to the sun's energy. Even fossil fuels like coal, oil, and natural gas are essentially ancient solar energy stored over time. Therefore, solar energy encompasses a wide range of forms, but in a narrower sense, it refers to the direct conversion of solar radiation into photothermal, photoelectric, and photochemical energy.

Solar energy is unique in that it serves as both a primary and renewable energy source. It offers an abundance of free, locally available resources that do not require transportation, all while leaving a minimal environmental footprint. Solar energy has not only paved the way for a new way of life but has also ushered in an era of energy efficiency and environmental preservation, benefiting both society and humanity as a whole.

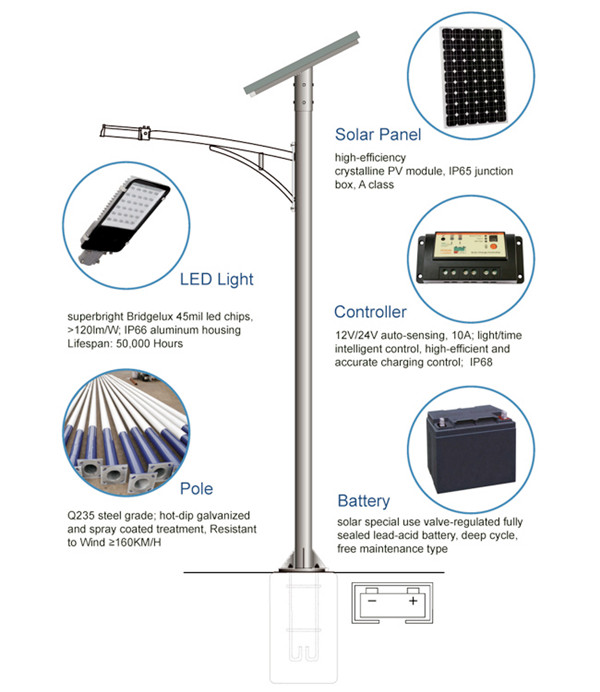

A solar LED street light comprises several key components, including solar panels, solar batteries, solar controllers, primary light sources, battery boxes, main lamp holders, light poles, and cables. Among these, the primary components are the solar panels, lamp holders, batteries, and controllers. The following is a detailed breakdown of these elements, along with an overview of the critical aspects of solar panel selection and placement, including the heat island effect:

①. Solar Panels

Solar panels are the core components of a solar LED street light, responsible for converting solar radiation into electrical energy. Commonly used solar cells include monocrystalline silicon, polycrystalline silicon, and amorphous silicon. The choice of solar cell type depends on the local climate and sunlight conditions. Polycrystalline silicon solar cells are suitable for regions with abundant sunshine, while monocrystalline silicon cells are more stable in areas with frequent cloudy days.

Solar cells typically have an open-circuit voltage ranging from 0.48 to 0.6 volts under standard conditions. These individual cells are connected and packaged to form solar cell modules, commonly referred to as solar panels. Two prevalent packaging methods are the lamination process and glue dispensing process. Lamination offers better durability and a theoretical working life of over 25 years.

Solar panels exhibit five essential electrical parameters:

* Short-circuit current (Isc)

* Peak current (Im)

* Open-circuit voltage (Voc)

* Peak voltage (Vm)

* Peak power (Pm), represented as Pm = Im × Vm

The peak power (Pm) represents the maximum output under standard conditions (STC), including a radiation intensity of 1000W/m², air quality at AM1.5, and a cell temperature of 25°C. The actual output power depends on solar irradiance, spectral distribution, and cell temperature, varying with time and location.

The output power of a solar cell per square meter is approximately 120W. This power increases as the conversion efficiency improves. The selection of solar cell module power should consider the street light's power, usage duration, and local climate conditions.

To prevent the heat island effect, solar cells are typically angled to avoid obstruction by leaves or other objects for extended periods. The ideal installation angle varies with the latitude of the installation area. In the area south of the Yangtze River, an angle of around 30° is recommended; in the area north of the Yangtze River, approximately 45° is suitable, and in the northeastern region, around 50°. The direction should be either due south or 50° west. Placing solar cells horizontally may reduce their output power by 15% to 20%.

②. Solar Controller

The solar controller plays a critical role in the solar lighting system and significantly impacts its overall lifespan, especially that of the battery. It employs an industrial-grade MCU (Microcontroller Unit) as the primary controller. By monitoring various parameters, including the ambient temperature, voltage, current, and other aspects of the battery and solar cell components, it assesses and manages the system, controlling the activation and deactivation of MOSFET devices to facilitate various control and protection functions.

In simple terms, regardless of the size of the solar lamp, a high-performance charge and discharge controller is essential. To enhance battery longevity, the controller must regulate the charging and discharging conditions, preventing overcharging and deep discharging. In regions with significant temperature variations, capable controllers should incorporate temperature compensation functions. Moreover, solar controllers should possess street light control functionality, incorporating both light control and time control features. Automatic load switching during the night is also essential to extend the operating hours of solar LED street lights during rainy days.

For any solar lighting system, the quality of the charge and discharge control circuit is pivotal to the system's success. Managing battery charging in a photovoltaic power generation system is more intricate due to the fluctuating energy input from solar photovoltaic power. An adept photovoltaic controller should offer various protection mechanisms, such as controlling battery charge and discharge, temperature regulation, maximum power tracking, overcharge protection, over-discharge protection, short circuit protection, and reverse connection protection. Additionally, it should include features like automatic switching and time adjustment to ensure reliable system operation. Moreover, the photovoltaic controller should intelligently optimize the solar cell module's power output under varying temperature and solar irradiation conditions, ensuring high system efficiency.

In figurative terms, the controller can be considered the backbone and the "heart" of the street lighting system. Just as a healthy heart ensures the proper functioning of the entire body, the quality of the controller profoundly affects the solar street light system's longevity and performance. When choosing a solar controller, it is advisable to opt for reputable brands like LEDER Lighting, OHW mall, and others.

③. Battery

In a solar photovoltaic system, the battery is a crucial component due to the inherently variable nature of energy provided by solar cells. Therefore, it is imperative to incorporate batteries with appropriate capacity and dependable performance to ensure the consistent operation of the solar photovoltaic system. Typically, maintenance-free lead-acid batteries are used in solar photovoltaic lighting systems.

Maintenance-free lead-acid batteries are fully sealed, boasting a high discharge rate and stable characteristics. They eliminate the need for water replenishment and offer a straightforward installation process. These batteries are versatile, suitable for both horizontal and vertical positioning, and typically come with an expected lifespan of 5 to 7 years.

When selecting the battery capacity, the general principle is twofold: it should meet the nighttime lighting requirements and store as much energy as possible generated by the solar cell components during the day. Simultaneously, it should also cater to the electrical needs during continuous rainy days to ensure uninterrupted nighttime lighting. Insufficient battery capacity may result in inadequate nighttime lighting, while an excessively large capacity can lead to prolonged power loss, ultimately shortening the battery's lifespan and wasting unnecessary investment.

A straightforward approach to determining their relationship is ensuring that the solar cell power output exceeds the load power by at least four times for the system to function correctly. The solar cell voltage should surpass the battery's working voltage by 20 to 30% to facilitate proper battery charging. Additionally, the battery capacity should be at least six times higher than the daily load consumption.

As a component responsible for storing and discharging electrical energy, the battery can be installed on a light pole or buried underground. When situated underground, a battery box serves the crucial role of safeguarding the battery from corrosion by underground water. The battery operates based on the principle of converting solar energy during the day, storing the electrical energy generated by photovoltaic modules, and discharging it at night as directed by the controller.

It's worth noting that product quality varies significantly among manufacturers with different technical capabilities, often reflected in their respective prices. Therefore, careful consideration of the manufacturer and their product quality is paramount when selecting batteries for your solar photovoltaic system.

④. Types of Solar Lights

LED street lamp heads come in various power specifications, including 20W, 30W, 40W, and 50W. Higher power generally corresponds to greater brightness. From a cost-efficiency standpoint, 30W solar street lights are typically sufficient for road lighting requirements. It's crucial to emphasize that the 30W specification represents the actual power, and this actual power directly correlates with the battery capacity.

⑤. Solar Street Lamp Post

The primary role of the lamp pole is to secure the streetlight head and solar bracket, typically taking the form of a tapered pole. Solar streetlights generally range in height between 4 to 7 meters. The material used for the lamp pole significantly impacts its lifespan. Commonly utilized materials include galvanized and hot-dip galvanized poles. Galvanized poles tend to have a lower cost but are more susceptible to rust, while hot-dip galvanized poles can typically withstand rust for up to 20 years.

Various specifications exist for the thickness of light poles, such as 2.5MM, 2.75MM, and 3MM. Customization based on the customer's initial design requirements for pole type and configuration parameters is also possible. Different size and style preferences lead to considerable price variations.

Solar street lights rely on crystalline silicon solar cells for power, while maintenance-free valve-controlled sealed batteries (gel batteries) store electrical energy. They feature ultra-bright LED lamps as light sources and are managed by intelligent charge and discharge controllers. These lights serve as eco-friendly alternatives to traditional public electric street lighting, requiring no cable installation, no access to AC power, and no electricity bills.

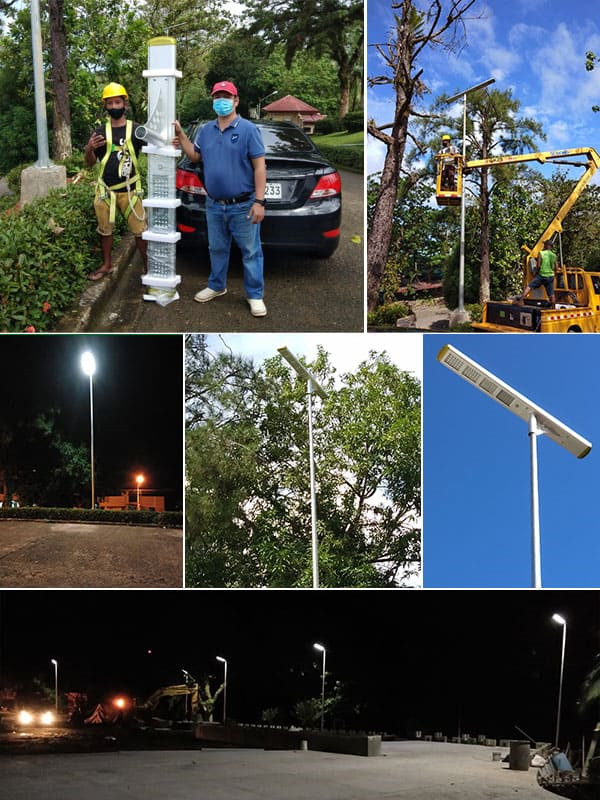

The construction and installation of solar street lights involve four primary stages: foundation construction, battery component installation, battery installation, and lamp installation. Let's delve into these steps:

(1) Foundation Pouring

① Start by determining the location for the standing lamp and conducting a geological survey. If the ground surface is soft soil within one meter, it's necessary to deepen the excavation. Ensure there are no other facilities (such as cables or pipes) beneath the excavation site and no long shadows cast by objects, as these may obstruct the lamp's operation. If necessary, consider relocating the lamp.

② Excavate a pit of 1.3 meters in accordance with the standard at the lamp's designated location. Position and pour the embedded parts in the pit's center. Place one end of the PVC threading pipe in the middle of the embedded parts and extend the other end to the battery storage area. Ensure that the embedded parts, foundation; and the original ground are at the same level (or the top of the screw aligns with the original ground, depending on site requirements). One side should be parallel to the road to ensure the lamp pole stands upright without tilting. Secure the embedded parts by pouring C20 concrete. During the pouring process, continuously employ vibrators to guarantee overall compactness and stability.

③ Upon completion of construction, promptly clean any residual mud from the positioning plate and use waste oil to remove impurities from the bolts.

④ During the concrete curing process, regular watering and maintenance are essential. The installation of the streetlamp itself can only commence once the concrete has fully solidified, typically after a waiting period of at least 72 hours.

(2) Installation of Battery Components

① Prior to connecting the solar panel to the controller, it's crucial to take precautions to prevent any short circuits between the positive and negative output terminals.

② Ensure a secure and reliable connection between the solar cell module and the bracket.

③ The output wires from the components should be shielded from exposure and securely fastened using ties.

④ Properly orient the battery assembly toward the due south, aligning it with the compass point for optimal performance.

(3) Battery Installation

① Exercise caution when placing the battery into the control box to avoid any damage to the control box.

② Securely fasten the connecting wires between batteries onto the battery terminals using bolts, and enhance conductivity by using copper gaskets.

③ Under no circumstances should short-circuiting occur after the output line is connected to the battery, as this may result in battery damage.

④ When connecting the battery's output line to the controller on the telephone pole, ensure it passes through the PVC threading pipe.

⑤ Following the above steps, thoroughly inspect the wiring on the controller side to prevent short circuits. Once normal operation is confirmed, securely close the control box door.

(4) Installation of Lighting Fixtures

① Secure each component in the following manner: fasten the solar panel to the solar panel bracket, affix the lamp head to the cantilever arm, then fix the bracket and cantilever arm to the main pole. Route the connecting wire to the control box (or battery box).

② Before hoisting the main light pole, perform a comprehensive check: verify the tightness of fasteners on all parts, confirm the correct installation of the lamp head, and ensure the light source is functioning correctly. After confirming the proper functioning through a simple system check, disconnect the solar panel connection cable from the controller, and the light source will activate.

③ When elevating the main light pole, prioritize safety precautions and secure the screws firmly. In case the component's angle deviates from the sun-facing direction, adjust the upper end to face fully southward.

④ Place the battery into the battery box and connect the wiring to the controller as per the technical specifications. Always connect the battery first, followed by the load, and then the solar panel. Pay close attention to the wiring, ensuring it aligns with the controller's labeled terminals. Avoid incorrect connections, polarity collisions, or reverse connections to prevent damage to the controller.

⑤ Conduct a thorough system check to verify its proper operation. First, disconnect the solar panel connection cable from the controller, which will turn the light on. Reconnect the solar panel connection cable, which will turn the light off. Carefully observe any indicator light changes on the controller. If everything operates as expected, seal the control box securely.

(1). LED Light Source:

Many landscape companies utilize LED light sources; however, disparities in technological quality can lead to variations in product performance, especially concerning brightness, light degradation, and service life. Here's an overview of high-power LED light sources to consider when choosing related products:

①. Select High-Power LEDs:

Opt for a single high-power LED, typically ranging from 30W to 100W, as the light source. A unique multi-chip integrated single-module light source design is recommended. The use of high-brightness chips, preferably imported, is advisable.

②. Integrated Radiator and Lamp Housing:

Seek designs where the radiator and lamp housing are integrated. The LED should be directly connected to the housing, facilitating heat dissipation through the housing's cooling fins and air convection. This ensures the LED street light's service life surpasses 50,000 hours. With a daily 12-hour operation, this lifespan exceeds 10 years, leading to minimal maintenance costs.

③. UV and Corrosion Resistance:

Verify that the lamp's surface is treated for ultraviolet and corrosion resistance. It should be sealed with high-temperature-resistant foamed silicone to effectively prevent dust and water ingress. The overall lamp protection should meet IP65 standards.

④.Reflective Design:

Look for products that employ a single elliptical aluminum reflective cavity and a multi-curved vacuum-coated reflector. This design controls the light emitted by the LED, enhancing the uniformity of light output and light energy utilization. It better highlights the energy-saving advantages of LED street lights, capable of saving over 70% in electricity compared to traditional sodium lamps.

⑤. Anti-Glare and Flicker-Free:

Choose lights that eliminate unpleasant glare and flicker, improving driving safety by eliminating glare, visual fatigue, and line of sight interference caused by standard street lights.

⑥. Instant Start-Up:

Prioritize lights that initiate without delay. They should reach normal brightness immediately upon powering on, eliminating the extended start-up process characteristic of traditional street lights.

⑦. Environmentally Friendly:

Ensure the product is green, eco-friendly, and free from pollution. It should not contain lead, mercury, or any other polluting elements that might harm the environment.

⑧. Compatibility with Solar Energy:

Opt for lights that seamlessly complement solar energy. These lights should maximize the advantages of LED DC low-voltage operation, emphasizing energy conservation and environmental protection. The integration of solar photovoltaic panels and LED light sources achieves optimal cost-performance and high reliability for customers.

(2) Solar Panels

The solar panel consists of high-efficiency crystalline silicon solar cells, ultra-white cloth-grained tempered glass, EVA, transparent TPT backsheet, and an aluminum alloy frame. It possesses a long service life and robust mechanical resistance to external pressure. Typically, solar panels employ either monocrystalline or polycrystalline technology, with the former being more expensive. As customers may lack professional measuring instruments for purchases, it is recommended to evaluate size, area, and weight. A larger size and area are directly proportional to the panel's power output.

Key considerations when selecting solar panels include:

①. Mechanical Strength:

Panels should provide adequate mechanical strength, ensuring they can withstand the stresses caused by transportation, installation, usage, impact, vibration, and hail damage.

②. Sealing Properties:

Panels must exhibit effective sealing properties to safeguard solar cells against wind, water, and atmospheric corrosion.

③. Electrical Insulation:

They should demonstrate excellent electrical insulation capabilities.

④. UV Resistance:

Panels should be highly resistant to UV radiation.

⑤. Flexible Voltage and Power Design:

Panels should be designed to meet various voltage, current, and power output requirements, offering different wiring methods to accommodate different needs.

⑥. Efficient Series and Parallel Connection:

Solar cells' series and parallel combinations should result in minimal efficiency loss.

⑦. Reliable Cell Connection:

Ensure the solar cells are reliably connected within the panel.

⑧. Long Working Life:

Solar cell modules should offer a long service life, exceeding 20 years under natural conditions.

(3) Batteries

Batteries serve as energy storage devices for solar panel power generation and as power carriers for nighttime lighting. Solar street light batteries are generally categorized into three types: lead-acid batteries, gel batteries, and lithium batteries, with gel and lithium batteries being the most commonly used. The cost of lithium batteries is higher than that of gel batteries, and gel batteries are more expensive than lead-acid batteries. To address environmental concerns and optimize battery replacements, certain requirements should be met:

①. Environmental Benefits of Lithium Batteries:

Lithium batteries offer environmental advantages, emitting no CO2 or SO2 and producing no noise, solid waste, or other pollutants associated with conventional power generation. They are a crucial component of contemporary renewable energy technologies.The outer shell should provide waterproof, moisture-resistant, anti-corrosion, thermal insulation, and other functions, enhancing the overall durability and performance of the battery.

(4) Solar Street Lamp Post

When considering lamp poles, factors like height, shape, and parameters play a significant role in the decision-making process. Taller lamp poles typically come with higher specifications and, consequently, a higher price tag. Similarly, more complex pole shapes also contribute to increased costs.

①. Height and Arrangement:

For two-arm road street lights, both double-sided and single-fire lamps are used. The lamps for motor vehicle lanes are positioned 11.5 meters from the ground, while sidewalk lamps are installed at a height of 8.5 meters. They are arranged crosswise on both sides with a spacing of 50 meters. The light source for express road illumination consists of three 120W LED street lights, while sidewalk illumination employs 80W LED street lights.

②. Material and Construction:

Lamp poles are constructed from high-quality Q235A steel, with silicon content not exceeding 0.04%. Quality brands like Shanghai Baosteel, Maanshan Iron and Steel, and Shougang are used as references. The tapered pole is formed in a single bending step and is composed of 4mm thick steel plate. The wall thickness does not include the thickness of the galvanized layer. The main pole is tapered, with an upper opening diameter of approximately 85mm and a lower opening diameter of around 200mm. Pick-up poles are constructed from 60mm diameter steel pipes, measuring 1.6 meters in length for motorways and 1.2 meters for sidewalks, with a wall thickness of 3mm.

③. Surface Quality:

The lamp pole's surface should be smooth, with no visible cracks, missing welds, continuous pores, undercuts, or irregularities. The centerline straight-line error should not exceed 0.02% of the pole length. The pole should exhibit a uniform appearance without unevenness, traces, or obvious defects.

④. Welding and Fastening:

The lamp pole is created using an automatic sub-arc welding method and subjected to ultrasonic flaw detection, meeting industry welding standards. The pole socket is securely fixed with nails and top screws.

⑤. Corrosion Resistance:

The lamp pole undergoes hot-dip galvanization for corrosion protection, ensuring a zinc layer of not less than 75 microns. The surface is practical and smooth, with consistent color. It should not peel or detach even after a hammer test. The galvanized life expectancy should be no less than 20 years.

⑥. Powder Coating:

The lamp pole is coated with high-quality outdoor pure polyester plastic powder, with color selection as per agreement. The surface should be flat and smooth, with a stable and durable plastic layer. It should not fade or flake off, and it must exhibit strong adhesion while being resistant to intense ultraviolet rays. The expected service life should be no less than 20 years, with a thickness of at least 80 microns, conforming to the ASTM D339-83 standard.

The adoption of solar photovoltaic power generation marks an irreversible shift in energy utilization. South America has emerged as the world's second-largest electricity consumption market, following the United States, and is experiencing the highest demand growth rate worldwide. However, the scarcity of petroleum and coal resources renders existing power generation methods insufficient to meet the escalating demand for electricity. The rapid promotion of solar power generation is imperative, with immense market potential. By targeting this market and expediting development, the solar cell industry is poised for substantial growth.

As Earth's resources become scarcer, investment costs for traditional energy sources increase, and concerns about safety and environmental pollution proliferate. It is within this context that solar lighting products have gained prominence alongside the popularity of solar water heaters. Here, we provide a practical comparison of the impact of solar lamps versus commercial lamps.

As a professional LED solar street light manufacturer, we understand the importance of providing clear and comprehensive information about solar street light components, their working principles, installation steps, and how to choose the right solar street lights.

At LEDER Lighting, We aim to assist customers in making informed decisions and are always ready to provide guidance and collaboration. we take pride in delivering high-quality, eco-friendly LED solar street lights that offer efficiency, reliability, and cost savings. We welcome your inquiries and look forward to guiding you through the process of implementing solar lighting solutions for your projects. Contact us today to learn more about our products and explore potential collaborations.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China