LED controllers can be classified in various ways, depending on factors such as their complexity, the type of LEDs they control, whether they are wired or wireless, and the specific application scenarios they are best suited for. Therefore, choosing the most suitable LED controller depends on which category is most important for your needs. For example, if you decide to control LED lighting wirelessly, you won't need to consider other categories of controllers.

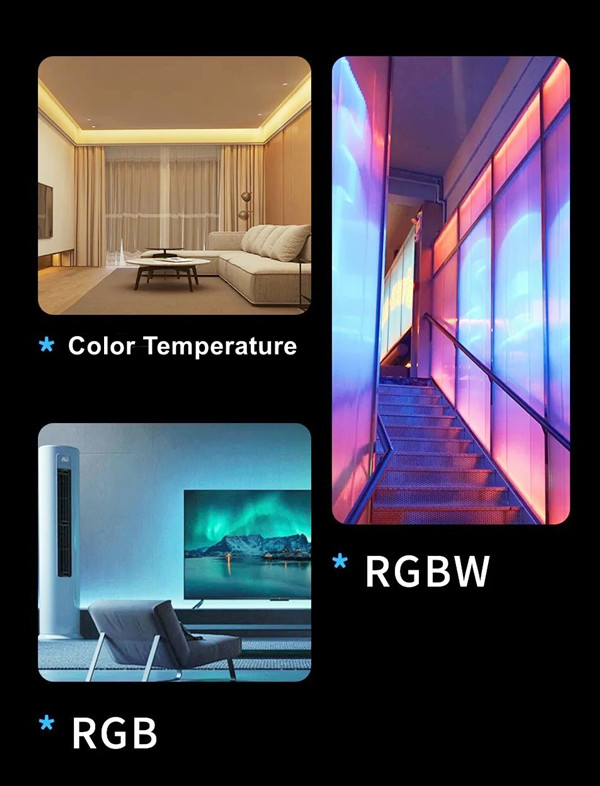

In general, most LED controllers, whether digital or analog, consist of various electronic components, including microcontrollers, and often feature integrated power supplies or remote power sources. These electronic components adjust the power, control, and protect the LEDs based on user inputs, sensor inputs, or predefined automation. LED controllers can also "mix" the brightness of individual color channels to achieve the desired color output. For instance, the brightness of the red channel in RGB (Red, Green, Blue) LEDs can be increased to produce red light. RGB LED lights can create over 16.7 million color combinations.

Regarding the power supply for LED controllers, it's important to note that LED controllers require direct current (DC) power for two primary reasons:

(1)They power DC devices (LED lights).

(2)They involve electronic circuits and semiconductors, making them DC-powered devices themselves. However, sometimes they may have an alternating current (AC) power input, which is then converted into DC power within the controller circuit (using rectifiers).

LEDs have unique advantages compared to other gas-discharge light sources, such as not requiring preheating and pulse triggering. They can operate at very low safe voltages. To fully utilize these advantages of LEDs, it is crucial to design high-performance LED control devices that ensure the benefits of LED lighting are fully realized. When embarking on the design of LED control devices, the first step is to determine the category of the designed LED control device based on the classification requirements in industry standards.

(1) What are the characteristics of LED self-type control devices?

LED self-type control devices refer to control devices where the internal output circuit is inherently connected to the power supply circuit. While the output voltage of such control devices can match the SELV voltage level, due to their non-isolated output characteristics, the voltage-to-ground at each output terminal may not always meet SELV requirements in various usage scenarios. Such control devices are not classified as SELV-marked LED control devices. For built-in control devices, their protection against electric shock should meet at least the requirements for basic insulation, and for independently installed control devices, it should meet the requirements for Class I and Class II protection against electric shock.

Application Scope: These control devices have relatively high conversion efficiency because they do not employ isolation measures internally. They are generally suitable for situations where the output voltage does not need to reach SELV levels or where there is sufficient additional protection against electric shock in lighting fixtures.

(2) What are the characteristics and requirements of LED equivalent SELV or isolated control devices?

In terms of protection against electric shock, this type of LED control device can be viewed as an isolated transformer with enhanced insulation function between the primary winding and the secondary winding. For the internal circuits and components between the output circuit and the power supply circuit (including PCB circuits and internal components of the isolation transformer) with voltage not exceeding 250V from the power network, the following requirements apply:

① The creepage distance and electrical clearance should be no less than 6mm (varies according to pollution degree).

② At rated power supply voltage, the output voltage at the input terminal should not exceed the SELV limit (effective value less than or equal to 50V). If loaded at rated load, the maximum output voltage should be less than or equal to 25V (effective value), the unloaded output voltage should be less than or equal to 33V (effective value), and the peak voltage should be less than or equal to 33√2V, in which case the output terminals can be exposed.

③ The capacitors bridging between the output terminals and the power supply circuit for EMC protection or control requirements should be Y1 capacitors or two series-connected capacitors with identical parameters.

Application Scope: These control devices should be installed within luminaires or enclosures with similar protective functions. However, when meeting the above-mentioned conditions, output terminals may have protection against electric shock and can be exposed.

(3) What are the requirements for independent SELV control devices?

In addition to meeting the requirements of "equivalent SELV or isolated control devices," independent SELV control devices must also meet the following requirements:

①Marking:

As it is an independent installation, it can be understood as the electrical box part of the luminaire. According to luminaire requirements, there should be a maximum ambient temperature marking when in operation, represented as "ta value"; if not marked, it is considered as ta-25°C.

Independent SELV control devices have the following unique markings on their product labels:

Indicates that this control device belongs to safety isolation.

Indicates that this control device has automatic protection against safety failures when it fails (internal short circuit).

Indicates that the output terminals of this control device do not have short-circuit protection.

Indicates that the output terminals of this control device have short-circuit protection.

② Heating Limits of Control Device Internals and Support Components:

When the LED control device operates under conditions of ta ambient temperature and 1.06 times the rated power supply voltage, the temperature of the transformer windings should not exceed the specified values in Table 5-3.

③ Maximum Temperature Rise Value under Short Circuit or Overload Conditions:

The LED control device, when operating at 0.94 to 1.06 times the rated power supply voltage and in a short-circuit or overload state, must not exceed the maximum temperature rise values as specified in Table 5-4.

④Periodic Tests for Magnetic Cores and Windings of Control Devices:

Application Scope: The inverter of independent SELV LED control devices (including magnetic cores and windings) should undergo 10 cycle tests for heating, damp heat, vibration, insulation, and withstand voltage at the specified corresponding temperatures. Three samples are used for testing. After completing the 10-cycle tests, only one sample is allowed to have an internal winding short circuit, but breakdown between windings and magnetic cores is not allowed.

Independent SELV LED control devices are suitable for use in situations without additional luminaire protection. If they have the appropriate IP (dust and water resistance) rating, they can also be directly installed outdoors. Such control devices are generally used as electrical box parts for sub-class luminaires and are used in conjunction with dish-type luminaires. If their output voltage is controlled to not exceed 12V, they can be used directly for luminaires in swimming pools and wading pools (where both people and luminaires are in the water).

For this reason, international standards related to control devices for lighting fixtures specifically stipulate that "the control terminals must have at least basic insulation from the power circuit. When the control terminals claim to be able to directly connect to Safety Extra Low Voltage (SELV), the control device's internal control circuitry and power circuit must have reinforced insulation." This means that control devices for LED lighting with dimming capabilities must meet enhanced insulation requirements for creepage distance, electrical clearance, and dielectric strength between the internal control circuitry and power circuitry on the circuit board, between components, and within isolating transformers. In this regard, the use of optocouplers and appropriate isolating transformers is a preferred solution to meet these enhanced insulation requirements. Note: The insulation material thickness between the optical components of the transformer's internal partition or optocoupler, serving as reinforced insulation, should be 20.4mm.

One significant factor that strongly influences the complexity of LED controllers is whether they have a built-in power supply (also acting as a voltage regulator/driver) or if the controller and power supply are separate devices. LED controllers with built-in power supplies are more compact and user-friendly (referred to as integrated driver controllers), making them typically suitable for smaller lighting projects where space and simplicity are crucial factors to consider. On the other hand, LED controllers without built-in power supplies offer great flexibility since power sources can be chosen independently based on the lighting's power requirements. This means they can be used for various applications.

When thinking about LED controllers or smart lighting, you might immediately think of your smartphone. By setting up the lighting correctly and downloading an application, we can extensively control the brightness and color temperature of lighting using a smartphone. However, using an app to control LED lighting is just one method of control; this is an example of wireless (typically based on Wi-Fi or Bluetooth) controllers. LED controllers come in both wired and wireless varieties, and there are different types of wired and wireless controllers. Wireless controllers can only be digital, while wired controllers can be digital or analog. Before we delve into this, let's first define what wired or wireless controllers mean. When we talk about wired or wireless LED controllers, we are actually discussing how the controller communicates with the LEDs, what method of wired or wireless communication technology it uses, and how it captures user input (control commands). For example, two different types of wireless communication are Wi-Fi and Bluetooth.

Wired LED controllers communicate with LEDs through cables. Their communication range is limited by the length of the cable and is typically harder to install. However, they are less susceptible to interference and are usually cheaper than wireless LED controllers because they require fewer components and less complex technology (for example, they don't need wireless receivers or transmitters).

Examples of analog and digital wired controllers include:

(1) Analog

0 - 10V dimming

Bidirectional thyristor

(2) Digital

DMX

DALI

PWM (Pulse Width Modulation)

BACnet

Wireless LED controllers communicate with LEDs wirelessly, and both the controller and the fixtures have independent power sources. There are two main advantages of using wireless LED controllers: range and ease of installation (no need for control wiring). The communication range of wireless controllers may vary depending on the type of wireless LED controller used. For example, Bluetooth signals might have a limited range, but if you use a Wi-Fi controller for lighting control and can control the fixtures through a cloud-based application, you can control them from anywhere in the world. In this case, you are essentially only limited by internet access. It's worth noting that if you use a Bluetooth controller with a smart bridge, that controller can have a range similar to a Wi-Fi controller.

Wireless controllers can only be digital (not analog). Here are some examples:

RF (radio frequency - various frequencies)

IR (Infrared)

ZigBee

Bluetooth

Wi-Fi

Next, let's compare some of the most popular protocols used for controlling LED lighting.

(1)DMX LED Controller

DMX LED controllers are wired digital lighting controllers that use the DMX protocol for communication, typically featuring 512 channels. Typical DMX controllers can control up to 512 monochrome lights or 170 RGB lights, so they have limitations in terms of the number of lights they can control, especially when precise control of lighting color or temperature is crucial. Although they technically have a range of up to 1,800 feet, optimal performance is usually achieved within 500 feet. DMX LED controllers use a digital control system or Digital Multiplexing (DMX), making them suitable for controlling larger lighting installations like bridges, building facades, and other outdoor projects. These controllers use low-voltage DC power and are commonly used in commercial and industrial applications, as they provide precise control of lighting fixtures and are well-suited for applications that require high-quality lighting. However, they can be costly and require more cabling and installation time, making them more complex to install than other lighting systems.

(2)DALI LED Controller

DALI lighting controllers are wired (two-wire) digital LED controllers that use the Digital Addressable Lighting Interface (DALI) system. DALI is an international standard for lighting communication (IEC 62386), ensuring compatibility between components from different manufacturers labeled with the DALI logo. One of their key advantages is that they are bidirectional controllers, meaning that if a fault occurs, lighting fixtures can notify the controller, and vice versa. The controller can also be individually addressed and programmed, allowing for easy grouping. This makes them flexible enough to be used in various applications (as lighting systems can be reconfigured without rewiring). Overall, DALI controllers are an excellent choice for precise and flexible control of lighting systems in commercial and industrial environments.

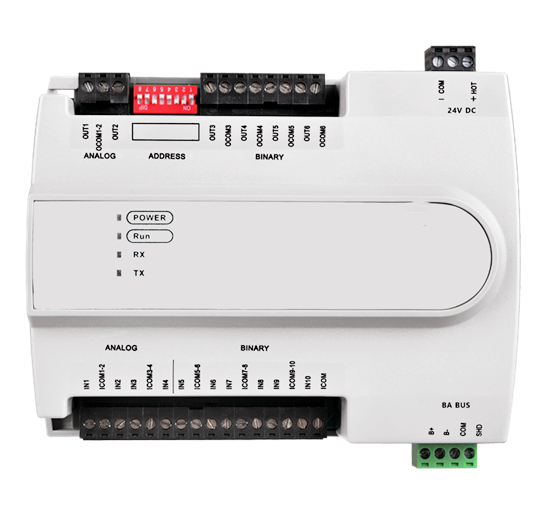

(3) BACnet LED Controller

BACnet (Building Automation and Control Network) lighting controllers are wired digital controllers that use the BACnet protocol for communication between devices and system networks. The BACnet protocol is not limited to facilitating communication between LED controllers; it is widely used in building automation and control networks, allowing different systems (e.g., HVAC and security systems) to communicate with each other. In simple terms, BACnet enables devices from different vendors to communicate, allowing existing building systems to expand without worrying about compatibility with new devices. For example, BACnet lighting controllers can be integrated into larger BACnet systems in a building (even if they are from different manufacturers), which makes centralization and monitoring easier. As they can connect to other BACnet systems, BACnet lighting controllers can be a valuable addition to building automation solutions that already use BACnet devices. BACnet LED controllers also offer precise control, aiding in supporting energy efficiency and customization. It's worth noting that when selecting, check if there is a built-in BACnet protocol interface so that the device can communicate with existing BACnet devices (including other lighting and HVAC systems in the building).

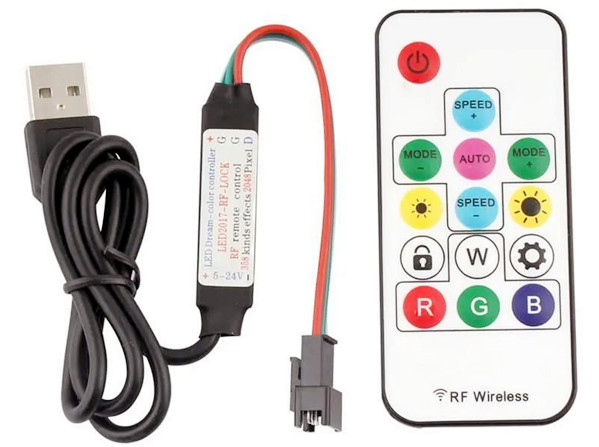

(4) RF (Radio Frequency) LED Controller

RF (Radio Frequency) LED lighting controllers use wireless communication to control LED lights. RF LED controllers transmit radio signals to receivers connected to LED lights. The receiver then decodes the signal and changes the brightness, color, or patterns of the LED lights based on the controller's commands. RF LED lighting controllers operate on specific frequency bands and have varying ranges depending on the communication protocol, environment, and the quality of the controller and receiver. A general rule of thumb is that higher RF frequencies have shorter communication ranges, while lower frequencies have longer ranges. For example, this means that Bluetooth (BLE - Bluetooth Low Energy) has a shorter range compared to devices like ZigBee because Bluetooth operates at 2.4 GHz, while Zigbee operates at 915 MHz (in North America). RF controllers are widely popular due to their ease of use, convenience, and flexibility. They do not require any physical connections between the controller and the lights. They find applications in residential environments, such as homes, apartments, and outdoor spaces, and can also be found in small commercial applications, like restaurants and retail stores. RF controllers are typically categorized as single-zone controllers or multi-zone controllers. Single-zone RF controllers allow control of a group of connected LED fixtures but cannot individually address lights within a group/zone. On the other hand, multi-zone controllers enable individual management of multiple LED groups/zones. For instance, a multi-zone controller can be used to turn off the lights in the lounge while keeping the lights in the conference room at full brightness.

(5) EnOcean RF Controller

EnOcean devices are an example of RF controllers. EnOcean devices are wireless, self-powered (energy harvesting), and operate without the need for batteries or wires. They charge themselves using kinetic energy every time a button is pressed. EnOcean technology is primarily used in building automation systems and can be applied to control lighting.

(6 )Wireless Networks and Bluetooth

Wi-Fi LED controllers are perhaps the most common and well-known LED controllers. They are wireless and digital. More notably, they require no cables and are typically controllable via compatible smartphone apps. Wi-Fi LED controllers have the furthest range of all wireless LED controllers, as they can control lighting from anywhere in the world with an internet connection. This makes them particularly advantageous in large-scale applications where the limited range of other controllers might hinder the ability to control lighting from one end of a large building to another. Some Wi-Fi controllers even offer voice control through their compatible apps. They also feature fast transmission rates, ensuring quick response of LED lights to commands. On the other hand, Bluetooth LED controllers are easy to install and also compatible with smartphones. They are typically the most energy-efficient and cost-effective choice. However, when not connected to a smart bridge, their range is limited compared to Wi-Fi controllers. A smart bridge essentially acts as a range extender because it enables Bluetooth LED controllers to connect to a Wi-Fi network, providing Bluetooth controllers with the same range as Wi-Fi controllers. Bluetooth controllers are often used in smaller spaces such as bedrooms or small offices, where their limited range is not an issue. Because it allows Bluetooth LED controllers to connect to a Wi-Fi network, this provides Bluetooth controllers with the same range as Wi-Fi controllers.

Most types of LEDs can be individually addressed and controlled, including RGB, RGB+W, tunable white LED lighting, and single-color LEDs. However, not every type of LED controller can control every type of LED. For example, RGB+W LEDs have four channels - red, green, blue, and white - while standard RGB LEDs have only three channels. Therefore, to control RGB+W LEDs, the controller must be capable of handling the additional white channel. It is essential to ensure that the chosen LED controller is compatible with the specific type of LED you plan to use.

Furthermore, while some controllers may be compatible with a certain type of LED, the controller itself may not have the capability to customize all the parameters that the LED can customize. For instance, perhaps a controller can only control the brightness levels of the LED, but the LED can emit various colors. Similarly, just because an LED controller can control LEDs (such as LED tube fixtures), it does not mean it is the ideal LED controller. For example, DMX and DALI controllers are most commonly used when controlling LED tube fixtures because they can achieve high-quality lighting customization (as mentioned above), and they are typically used in larger spaces (which LED tube fixtures also tend to illuminate). They are commonly employed in commercial and industrial applications because both DMX and DALI controllers are part of international standards, ensuring that different lighting components from various manufacturers can work together, making it easier for businesses to build complex lighting systems that meet their specific needs.

In conclusion, LED controllers are crucial in the world of smart, energy-efficient lighting. Choosing the right controller for your project can determine the level of comfort, convenience, and energy efficiency you can achieve in automating your lighting. Your choice largely depends on the LED lighting you want to control and the size of your lighting space.

For example, if you're just looking for an LED controller for the LED lights under a shelf in your bedroom, a Bluetooth LED controller will be able to provide all the automation features you need (and more), while being cost-effective and easy to install. However, if you wish to control and automate LED tube lighting in a commercial or industrial space, DALI, DMX, or BACnet LED controllers will work well. This is because these controllers typically support more loads, provide more power, and can offer the advantages of Wi-Fi LED controllers, such as an almost limitless range. Additionally, there may already be existing devices in the building that comply with the DALI or BACnet protocols, as these are standardized.

Another consideration is that if an LED controller doesn't have a built-in power supply, its equipment may be more expensive and complex compared to controllers with built-in power supplies. By better understanding the various factors involved in choosing an LED controller and the types of LED controllers available, it is hoped that this article can help you make informed decisions about selecting the right controller for your project.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China