Fluorescent lamps are also known as daylight lamps and are a commonly used type of indoor lighting. They operate by gas discharge and are brighter and more colorful than the incandescent bulbs we typically use. They have a strong decorative effect. LED lamps are lighting fixtures made from a semiconductor material chip that emits light electronically. LED lamps have excellent shock resistance. So, what are the differences between fluorescent lamps and LED lamps? Let's explore this together based on aspects such as the principle of illumination, brightness, and lifespan.

LED fluorescent lamps are widely used for indoor lighting in offices, factories, shopping malls, schools, and homes, among other places. Table 6-1 provides a performance comparison between traditional T2 fluorescent lamps and T8 LED fluorescent lamps.

Table 6-1 Performance comparison between traditional T8 fluorescent lamps and T8LED fluorescent lamps

|

Parameter |

T8 36W Inductive Fluorescent Lamp |

T8 18W LED Fluorescent Lamp |

Remarks |

|

Power |

Actual power 42W |

Actual power approximately 22W |

Approximately 47% energy savings |

|

Current |

0.30A |

0.1A |

Significant decrease in current |

|

Power Factor |

Around 0.5 |

Above 0.8 |

Significant improvement in power factor |

|

Brightness |

2460lm |

1440lm |

Approximately 1020lm decrease |

|

Illuminance |

45° at 2m, 112lx |

45° at 2m, 102lx |

Fluorescent lamps emit light at 360°, and the upward light needs to be emitted through a reflector, with an emissivity of 70%; LEDs emit direct light, so the actual effective illumination is basically the same |

|

Color Rendering Index (CRI) |

≤65, with color deviation compared to natural light |

≥80, providing brighter and more natural colors similar to natural light |

Significant difference in visual perception |

|

Lifespan |

Approximately 5000 hours |

Approximately 30,000 hours |

LED fluorescent lamp has a lifespan approximately 6 times longer than traditional fluorescent lamps |

|

Start-up |

Flickering during startup |

Flicker-free startup |

Noticeable difference |

|

Light Decay |

Light decay after approximately 3 months of use |

Light decay after approximately 1 year of use |

Longer maintained brightness |

|

Price |

Approximately ¥8.00 RMB |

Approximately ¥10.00 RMB |

LED prices are decreasing, showing a clear trend of lower overall prices |

|

Other Comparisons |

Flicker with potential harm to vision, causing eye fatigue and discomfort |

Flicker-free, creating lighting similar to natural light, reducing eye fatigue |

Significant difference in visual perception |

|

Generates electromagnetic noise and significant heat |

No noise, minimal heat generation |

Noticeable difference |

|

|

Contains 6-9mg of mercury, causing environmental pollution and radiation exposure |

Mercury-free, environmentally friendly with minimal radiation |

Achieves true green and eco-friendly lighting. |

Brightness:

LEDs vary in brightness, and their prices differ accordingly. LEDs used in LED fixtures should meet the antistatic capabilities of Laser Class I standards. LEDs with strong antistatic capabilities have a longer lifespan and, consequently, a higher price. Typically, LEDs with an antistatic rating greater than 700VH are suitable for LED lighting.

Wavelength:

LEDs with consistent wavelengths produce consistent colors, and achieving color consistency usually results in higher prices. LED manufacturers without spectrophotometers find it challenging to produce color-accurate products.

Leakage Current:

LEDs are unidirectional conductive light emitters, and any reverse current is termed leakage. LEDs with high leakage currents have shorter lifespans and lower prices.

Beam Angle:

Different LEDs have different beam angles depending on their intended use. LEDs with special beam angles (e.g., full diffusion angles) tend to have higher prices.

Lifespan:

The key differentiator in LED quality is lifespan, which is determined by lumen depreciation. LEDs with minimal lumen depreciation have longer lifespans and higher prices.

Chips:

The light-emitting component of LEDs is the chip. Different chips result in significant price differences. Chips produced in Japan or the United States are more expensive, while chips from Taiwan and mainland China are more affordable.

Chip Size:

Chip size is represented by its side length, and larger-chip LEDs generally offer better quality, with prices largely proportional to chip size.

Encapsulation Material:

Conventional LED encapsulation materials are usually epoxy resin, but LEDs with added UV resistance and fire retardants are more expensive. High-quality outdoor LED lighting should have UV resistance and fire resistance.

Every product is designed to suit different purposes. The reliability design of LED lighting includes electrical safety, fire safety, environmental suitability, mechanical safety, health safety, and safe usage time. From an electrical safety perspective, LEDs should comply with relevant international standards.

① Noise in the power supply, often caused by components like transformers.

②LED brightness fluctuates with variations in grid voltage, indicating poor or nonexistent constant current characteristics.

③ Flashing of LED lights occurs when turning off the power supply.

④ Flashing of LED lights when the power supply is switched on.

⑤ Low efficiency of the converter, resulting in higher heat generation.

⑥Significant variation in input power among LED fluorescent lamps from the same batch, sometimes exceeding 2 watts.

The above-mentioned issues are primarily related to technical problems in the design of LED drivers and are mainly attributed to improper selection of chips and design details in the driver circuit. If the driver is well-equipped with features, it can address most of the aforementioned problems.

Currently, many LED fluorescent lamp drivers employ buck converter circuits, with control chips such as HV9910 (as well as other chips similar to HV9910) being representative choices. However, there are certain design issues in the HV9910 series that result in operational difficulties. The main issues are as follows:

HV9910 operates at a relatively low working voltage. Due to the limited number of high-voltage MOSFETs available with low Vcs, it can only be used to drive regular high-voltage MOSFETs with compromised performance, leading to increased MOSFET USD(IN) and decreased conversion efficiency.

It operates in a buck converter circuit structure, and the freewheeling diode handling when the MOSFET is off is not ideal.

The relatively low drive voltage, coupled with the recovery time of the freewheeling diode, results in a common-state phenomenon when the MOSFET is in the "on" state. This increases MOSFET losses and heat generation, and the freewheeling diode also heats up.

MOSFETs are devices with positive temperature coefficients, and increased power dissipation causes the junction temperature to rise, leading to an increase in on-state resistance. As the on-state resistance increases, the temperature rises further, eventually causing the power supply to fail.

The HV9910 utilizes a fixed conduction time (OffTime) control method, which is considered an advanced control technique. However, it may not be suitable for certain interference detection issues and the design of the drive voltage itself. To effectively use this chip, it's essential to understand the electrical parameters of the HV9910. Otherwise, you may encounter problems during usage, including:

Verify if the frequency being used is suitable (consider factors like load, inductance, MOSFET, and HV9910's shutdown time together).

Pay attention to the interference handling of the CS current limit pin and make rational use of RC components.

Properly handle the MOSFET's drive circuit.

Choose the right fast-recovery diode (this is also crucial, whether you're using HV9910 or alternatives like QX9910 or PT4107, sometimes it can result in a temperature difference of approximately 8°C in the MOSFET, which engineers often overlook).

Make effective use of the two feedback control pins (pay special attention to their timing and control aspects).

Ensure stable power supply to pin VCC and use appropriate power supply techniques.

Consider using your own circuit structure for expansion (if possible, you can try the SEPIC structure).

Implement interference handling techniques between the switching circuit and the power supply grid.

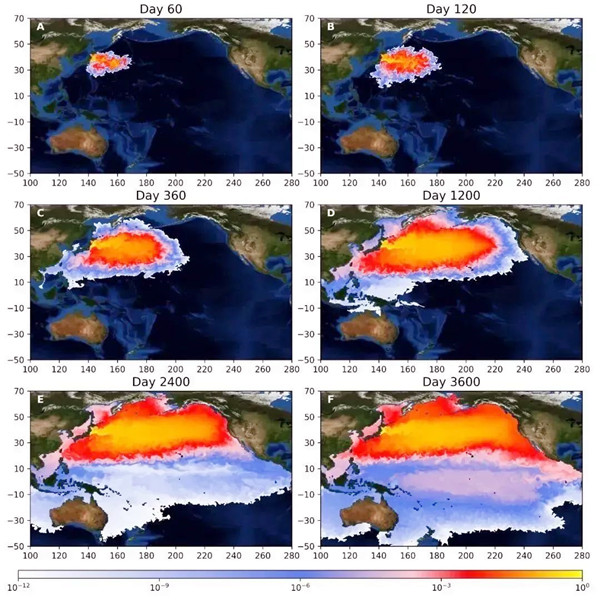

On August 24th, Japan's Fukushima Daiichi nuclear power plant began the discharge of radioactive water into the ocean. Research conducted by the German Marine Research Institute indicates that from the day of discharge, related radioactive materials can spread to most of the Pacific Ocean within 57 days. Three years later, contamination will reach the United States and Canada, and in ten years, it will spread to global oceanic regions.

China has suspended the import of aquatic products from Japan. However, the impact of Japan's discharge of nuclear-contaminated water on the safety of aquatic products and the supply chain will be profound and long-lasting. Adjustment and transformation of the global aquatic product supply chain have become inevitable.

Recently, news of a bountiful seafood harvest in Xinjiang, China, has become a hot topic. Salmon, tilapia, whiteleg shrimp, and Australian lobsters from Xinjiang are not only being sold domestically but also exported to countries such as Russia and Singapore. Behind this success lies significant investment and advancements in agricultural science. An information management system has been established, consisting of modern aquaculture monitoring systems, production process management systems, comprehensive management support systems, and public service systems. This system includes online water quality monitoring, automatic feeding systems, lifting systems, underwater robots, and comprehensive production process monitoring. It has greatly improved the information, automation, and intelligence levels of aquaculture bases, reducing production costs, increasing labor productivity, resource utilization, and management efficiency, and enhancing seafood quality and market competitiveness. This experience is worth studying.

Overall, Xinjiang's salmon farms are just a microcosm of the modern aquaculture development efforts in Xinjiang in recent years. In a world marked by escalating regional conflicts, self-sufficiency is imperative. Xinjiang's achievements can serve as an example for the world and inspire action.

① Aquaculture LED Lighting System Boosts Shrimp Production by a Remarkable 80%

In the survival and growth processes of aquatic species, light serves as a crucial and indispensable ecological factor, playing an extremely important role in their physiology and behavior [1]. The light environment consists of three essential elements: spectrum, photoperiod, and light intensity, all of which have significant regulatory effects on the growth, metabolism, and immunity of aquatic species.

② Development of Industrial Aquaculture Models

With the development of industrial aquaculture models, the demand for precise control of the lighting environment has become increasingly important. Scientifically setting up an appropriate lighting environment tailored to different biological species and growth stages plays a crucial role in promoting their growth. In the field of aquaculture, due to variations in the sensitivity to light and light preferences among different aquatic species, it is necessary to establish suitable lighting conditions based on their specific lighting environment requirements.

For example, some aquatic species are more suitable for spectra of red or blue light, and the lighting environment in their habitats can affect the sensitivity and preferences of their visual systems. Additionally, the lighting requirements may vary at different growth stages.

③ Traditional Fluorescent Lighting in Aquaculture

Currently, in aquaculture, there are several common farming methods, including pond farming, cage farming, and industrialized farming. Pond farming and cage farming primarily rely on natural light sources, which pose challenges in controlling the lighting environment. In industrialized farming, traditional daylight or fluorescent lamps are still widely used. These conventional light sources consume significant amounts of electricity, are prone to short bulb lifespans, and the disposal of harmful substances such as mercury after use can cause substantial environmental pollution, necessitating urgent solutions.

Therefore, in industrialized aquaculture, the selection of suitable artificial light sources and precise setting of light spectra, intensity, and photoperiods based on different aquatic species and growth stages will be a focal point of future aquaculture research. This approach aims to enhance production efficiency, economic benefits, reduce environmental pollution, and achieve green and sustainable development in aquaculture.

④ Traditional Fluorescent Lights vs. LED Light Sources: Which is Better for Aquaculture?

Traditional fluorescent lights have been one of the primary artificial light sources used in the aquaculture industry for a long time. They have low purchase and installation costs but come with several disadvantages. For example, they have a shorter lifespan in humid environments, cannot be dimmed, and may cause stress responses in fish. Additionally, the disposal of fluorescent lights can lead to severe water pollution.

With the rapid development of optoelectronic technology, Light Emitting Diodes (LEDs) have emerged as the fourth-generation emerging light source type, and their application in aquaculture is becoming increasingly widespread. In China, where aquaculture is a vital sector of the agricultural economy, using LED lights for supplemental lighting in industrialized farming has become an essential means. Compared to traditional light sources, using LED light sources for supplemental lighting can better meet the growth requirements of different aquatic species. By adjusting the light color, intensity, and duration, it can promote the normal growth and development of aquatic organisms, increase biomass and yield, reduce production costs, and enhance economic benefits.

LED light sources also offer advantages such as precise control of the lighting environment, long lifespan, and high energy efficiency. They serve as an environmentally friendly and sustainable lighting solution. Currently, in China, most lighting fixtures in aquaculture facilities are relatively inefficient. With the development and popularization of science and technology, LED lighting, which significantly improves yield and profitability in aquaculture, is promoting the transformation of fish production towards higher quality and environmental sustainability.

⑤ The Current State of Aquaculture Lighting in Aquaculture

Aquaculture is one of the vital pillars of China's rapidly developing agricultural economy and has become a frontier for innovation and development in modernized farming. In the context of standardized and scientific management in aquaculture, the use of fish pond lights underwater for supplemental lighting is an extremely important physical means and a significant measure for achieving precision management in aquaculture. With the Chinese government's emphasis on agricultural economic development, the scientific use of aquaculture lighting has become one of the pathways to achieving green and sustainable development.

Given the differences in characteristics between production workshops and natural environments in aquaculture enterprises, artificial lighting has become an indispensable component. Both light and dark environments can have adverse effects on the reproduction and growth of fish. To achieve production goals, the lighting environment must be matched with various factors such as temperature, water quality, and feed.

With the development of semiconductor technology and the continuous pursuit of environmental protection and efficient fish production, the use of LED lighting as a means to improve the efficiency of aquaculture production has gradually gained attention and widespread application.

Currently, there are successful cases of aqua culture-led light adoption in the aquaculture industry. Collaborations between research institutes and shrimp farming enterprises in Xinjiang have led to the establishment of specialized LED lighting research and application engineering technology centers for fisheries and the ocean. Through the customized design and installation of intelligent aquaculture lighting systems, shrimp production has increased by 80-90%, resulting in significantly higher profits.

Aqua culture led light technology has a positive impact on various aspects of the aquaculture industry, including development, production efficiency, costs, quality, safety, and green development. With continuous technological advancements, the prospects for aquaculture lighting technology in the aquaculture industry are becoming increasingly promising.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China