Although LEDs generate very little heat, the use of multiple-watt-level LEDs in LED lighting can produce high levels of heat. While LEDs are relatively efficient, this efficiency is mainly supported at low currents. At high currents and temperatures, their efficiency decreases. Additionally, LED types with phosphor coatings can generate heat during the wavelength conversion process. Prolonged exposure to high temperatures can reduce the lifespan of LED chips, phosphors, and packaging resins. To maintain the advantages of "high efficiency" and "long lifespan" of LEDs, it is necessary to control the LED's junction temperature.

LED power supplies differ significantly from those of incandescent and fluorescent lamps. Incandescent bulbs can be directly connected to 220V AC power. Although fluorescent lamps use ballasts and switching circuits, they still operate on 220V AC power. LEDs, on the other hand, require direct current (DC) with a constant current. Therefore, 220V AC power needs to be converted into DC power for LED operation. The efficiency of the power supply directly affects the overall efficiency of the lighting fixture, making it essential to improve power supply efficiency for LED lighting efficiency.

There are two primary methods for controlling LED light output: changing the constant current or using pulse modulation. LEDs emit light when electrons recombine with holes, and the light output depends on the current. At low currents, the light output is directly proportional to the current. However, as LED current increases, heat production also increases, leading to lower light emission efficiency, causing the light output to deviate from being directly proportional to the current.

In the method of changing the pulse duty cycle, the Talbot-Plateau effect (where the eye perceives the average brightness over time after repeated exposure to momentary flashes) allows for brightness control by altering the pulse duty cycle.

Compared to incandescent and fluorescent lamps, a single LED emits relatively little light, so multiple LEDs are often used. Furthermore, due to the small emitting area and high brightness of LEDs, looking directly at them can cause glare. To reduce glare, diffusers are used. However, using diffusers scatters light in various directions, reducing light efficiency.

LED, incandescent, and fluorescent lamps have different light distribution characteristics. Light distribution refers to the direction of light emission and the intensity of emission in different directions. Even for light sources with the same luminous flux, different light distribution can result in different illuminance distributions. Sometimes, there may be a decrease in illuminance in the desired area, while other areas experience an increase in illuminance.

To minimize light wastage and control light distribution, lenses and reflectors are used. LEDs inherently have advantages such as a small emitting area, light emission within a half-sphere, and rotationally symmetric light distribution. When combined with lenses and reflectors, they can form a good light source.

Another important aspect of light source properties is the spectrum. LED emission spectra are concentrated in a narrow range of specific wavelengths and do not emit infrared radiation. Therefore, LEDs are a better choice when you want to avoid heating the illuminated objects. However, LEDs themselves generate heat, so thermal management is necessary. Additionally, LED color temperature can change with temperature variations, especially in phosphor-coated LEDs.

1. Optical System:

The optical system of a lamp is its core, designed to ensure that the light emitted by the lamp complies with illumination requirements based on the characteristics of the selected light source. Typically, a lamp's optical system consists of a light source, lamp holder, and a translucent cover or reflector.

Compared to traditional light source fixtures, LED lamp fixtures' optical systems have the following characteristics:

① The optical system usually consists of LED chips and lenses, forming LED units or arrays. These LED units are often arranged on a flat aluminum base or a shaped substrate, with or without light diffusers.

LED units emit light in a 360° direction, which significantly differs from traditional light source fixtures.

Manufacturers combine multiple LED units on a board according to lighting needs, and ensuring the consistency of color temperature and color space uniformity among these LED units is essential for LED lamp fixtures' evaluation.

② LED's light and color properties are sensitive to the temperature of the PN junction. High temperatures and prolonged radiation can degrade phosphors' light conversion efficiency, leading to color shift. LED lamp lifespan assessment should consider temperature effects and assess light maintenance while limiting color shifts.

2. Electrical Components:

The LED driver power supply is a crucial element determining the performance of LED lamps and is one of the criteria for lamp selection or design. LEDs require constant current driving at low voltage, unlike incandescent bulbs that can be directly connected to 220V AC power. LED drivers are essential to convert the power source into suitable conditions for LED operation.

Electrical design for LED lamp fixtures should consider factors such as LED characteristics, quantity, installation location, and position in the electrical grid. It should address electrical safety, constant current driving, interference resistance, and electromagnetic interference (EMI). Proper LED driver selection or design is essential.

3. Thermal Management:

Like traditional light sources, LED lamp fixtures generate heat. Heat in LED lamp fixtures comes from losses during LED's photonic conversion and LED driver power. Effective heat management is crucial in LED lamp design to ensure LED chips' effective heat dissipation and to control the micro-environment within the fixture to maintain LED junction temperatures within acceptable ranges.

LED lamp structure and design should incorporate effective thermal management solutions. Temperature control points related to LED chips, such as solder points, bases, and fixture housings, should be identified, and the temperature of these points should be controlled. Selection of LED drivers with appropriate temperature ratings is also important for heat control.

4. Mechanical Components and Structure:

Mechanical components play a role in determining the placement and relationships between the optical, electrical, and thermal systems of the lamp. They ensure that the lamp is securely fixed and safe for use in the designated environment.

Traditional lamp mechanical systems include components such as lamp holders, wiring structures, sealing mechanisms, mechanical protection structures, lamp fixtures, and adjustment mechanisms. LED lamps, depending on the LED module type, may not have traditional lamp bases and instead use connectors.

5. Photobiological Safety of LED Lamps:

LEDs emit narrow-beam, high-brightness light. As LED efficiency and brightness increase, especially with high-power white LEDs, concerns about the potential harm of LED light radiation to humans have grown. LED light radiation can potentially harm the eyes and skin, including issues like photobiological hazards, near-UV hazards, retinal blue light hazards, no-lens retinal hazards, thermal hazards, and skin thermal hazards.

Due to these concerns, standards for evaluating the photobiological safety of LEDs have been developed, such as IEC 62471:2006. These standards assess the hazards associated with optical radiation and can be applied to evaluate the photobiological safety of LED lamp fixtures.

Mixing Up Brightness and Power Parameters:

Influenced by traditional incandescent bulbs, consumers often gauge the brightness of lighting fixtures using "wattage." Incandescent bulbs were typically discussed in terms of watts, without mentioning lumens. Over time, this habit has affected consumers' lighting fixture choices. LED technology is different from incandescent bulbs, and as LED efficiency continues to evolve, wattage alone cannot represent its lumen output. The fundamental parameter for brightness is luminous flux, measured in lumens (lm), which represents the total visible light emitted by a light source per second. Power (wattage) is a measure of electricity consumption.

There's a common misconception that higher LED wattage leads to brighter lumens, implying greater brightness. However, this is an incorrect understanding. For LEDs with the same wattage, higher lumen output means greater energy efficiency. For example, if a 7W LED bulb produces more lumens than an 8W bulb, the 7W bulb is actually more energy-efficient. Unfortunately, many lighting products found online often don't specify luminous flux, and this disadvantage is often overlooked. This is especially true for modern solar LED lamps such as solar street lights, solar floodlights, and solar wall lights. Manufacturers often advertise wattage while concealing the actual wattage because the luminous flux of solar LED lamps is determined by the total battery capacity.

Therefore, when selecting lighting fixtures for brightness, it's important to first identify luminous flux (lm) and then opt for lower wattage whenever possible. Making an LED lamp brighter is a straightforward task, but ensuring it is truly safe, energy-efficient, and durable is more complex.

Prioritizing Aesthetics Over Light Source Quality:

In an era that values personalization, many people are willing to spend a significant amount on unique and stylish lighting fixtures while neglecting the quality of the light source. Due to budget constraints, some may even choose low-quality or substandard products like lamp beads, spotlights, or light strips. These low-quality lights may generate excessive heat, leading to the burning out of fixtures, circuit damage, or even safety hazards.

It's important to understand that the light source is the soul of illumination, while the fixture is the body. High-quality light sources are fundamental to ensuring lighting quality. In contrast, brand-name fixtures tend to be standard, relatively simple, and minimalistic in design.

An example of this is a customer from Central Asia who inquired about our waterproof light strip prices, which were higher than those of other manufacturers. We directly showed the customer every material we used from our warehouse, explaining that our products were made from genuine materials. The customer had previously purchased light strips in October 2022, and they had malfunctioned within three months. After our material explanation, they realized that our products were indeed of high quality. It's crucial to remember that fixtures provide the housing for lighting, but the light source is the essence of illumination. High-quality light source products are the foundation for ensuring lighting quality, and more often than not, fixtures from reputable manufacturers are standardized, relatively simple, and minimalist in design.

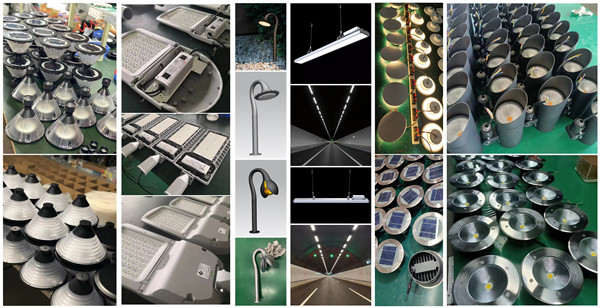

We take pride in our unique ability to provide fully customized LED lighting solutions to meet your specific lighting needs. Our team of experts excels at creating bespoke lighting solutions that go beyond the ordinary, ensuring your lighting fixtures align with your vision and project requirements. Join us today to explore the limitless possibilities of personalized LED lighting!

Firstly, we understand that every project is unique, which is why we are thrilled to introduce our expanded range of customized LED lighting solutions. Through such products, we bring you several advantages that go beyond standard lighting solutions.

Custom Solutions: Our expert team will work closely with you to design and craft lighting solutions that align perfectly with your project's specific requirements. Whether it's unique shapes, sizes, or color temperatures, we can turn your vision into reality.

Enhanced Aesthetics: Lighting plays a crucial role in setting the mood and ambiance of any space. With our custom services, you can obtain lighting designs that not only illuminate but also elevate the aesthetic appeal of your environment, setting your lighting LED company apart from others.

Improved Functionality: Your lighting needs are sure to vary based on your space's intended use. Our custom LED solutions are designed to provide the functionality you require, whether it's adjustable brightness, color options, or advanced controls.

Experience the Difference

To showcase the power of customization, we invite you to explore our new Custom Projects Library on our website . Here, you'll find inspiring project examples where we've transformed spaces using customized LED lighting solutions.

Start Today

If you have a project or would like to discuss how our custom services can benefit your upcoming venture, please feel free to reach out to our professional expert team. We are ready to collaborate with you to turn your lighting vision into reality.

We are committed to not only meeting your expectations but exceeding them. We look forward to embarking on this exciting journey of customization with you.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China