Efficient street lighting is a fundamental aspect of urban infrastructure, ensuring safety, visibility, and aesthetics in our cities and towns. The design of LED street lights plays a pivotal role in achieving the necessary road illumination, brightness, and uniformity. To meet these requirements, the optical system of LED street lights comprises a range of components and light distribution schemes. In this comprehensive exploration, we will delve into the key elements and various light distribution schemes involved in the design of LED street lights, shedding light on the intricacies of this vital urban lighting technology.

The optical requirements for LED street lights are crucial in achieving the necessary road illumination, brightness, and uniformity. Designing the light distribution to meet these requirements is a significant challenge in LED street light optics.

The Illuminating Society of North America (IESNA) standard classifies street lights into five categories, with categories 2 and 3 being the most commonly used for road lighting. The "Energy Star" standard for SSL provides a detailed description of LED street lamp light distribution. For outdoor Class 2 and Class 3 lamps, the light distribution requirements are as follows:

The maximum light intensity value should fall within the range of 55 to 65.

The light intensity value in the range of 0° to 25° should be between 10% and 35% of the maximum light intensity value.

The light intensity value in the range of 25° to 45° should be between 35% and 60% of the maximum light intensity value.

The light intensity value in the range of 65° to 75° should be between 35% and 95% of the maximum light intensity value.

The light intensity value in the range of 80° to 90° should be 5% of the maximum light intensity value.

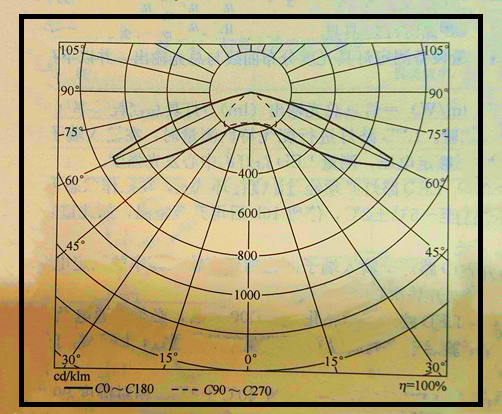

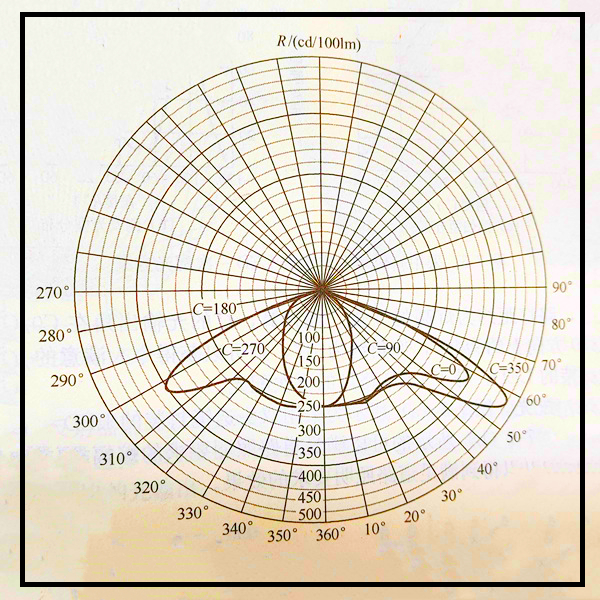

According to this standard, the most optimal light distribution for LED street lights is the bat-wing light distribution (refer to Figure 7-3). This distribution enhances road surface uniformity but can be challenging to achieve with approximately Lambertian light distribution. It's important to note that for street lights, the vertical distance between the light source and the road varies, with greater distances resulting in reduced illumination due to the inverse square law.

When light intensity remains constant, the farther the distance, the lower the illumination. Therefore, at larger angles from the vertical, light intensity should be minimized to reduce glare.

Typically, common expressway main road lights have light poles spaced at approximately 35 meters. To meet the requirements specified in the CJ]45-2006 standard, including average illumination (20Lx/30Lx), uniformity (0.4), and an environment ratio of 0.5, LED street lights must exhibit a strong output in the batwing curve shown in Figure 7-4. Different road types may have variations in the shape of their light distribution curves.

The optical system design of LED street lights typically comprises three main components related to light distribution: primary optical design, secondary optical design, and tertiary optical design.

The light distribution of the LED light source itself is a fundamental aspect of the lamp's optical design. If the chosen LED light distribution scheme is inappropriate, it can increase the complexity of the secondary optical design of the lamp. Therefore, the optical design of LED street lights must begin with the single LED's light distribution design.

(1) Light output characteristics of LED

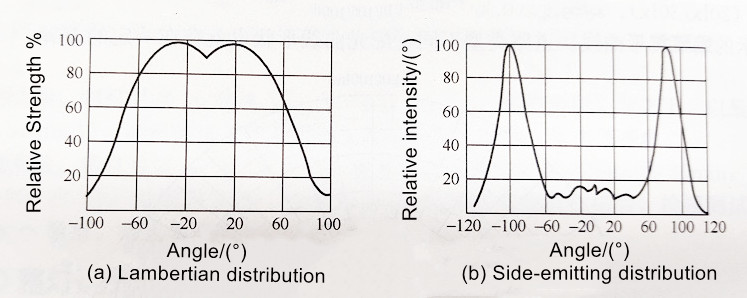

The light output characteristics of LEDs are influenced by the shape design of the high-power LED transparent encapsulation material, which is typically an optical lens design. When the same chip undergoes different packaging processes, the resulting light emission angle and light intensity distribution vary. In Figure 7-5, you can observe the light intensity output characteristic curves of several main types of LEDs.

Regarding the light intensity output characteristics of high-power white LEDs, Lambertian, bat-wing, and condenser types are commonly used. However, these types are seldom directly applied to street lights; they need to be redesigned to meet road lighting requirements and achieve the desired light output characteristics.

(2) LED Light Distribution Scheme

① LED Primary Light Distribution Scheme:

In the production of high-power LEDs, lens technology is used for packaging. Hence, it is possible to integrate LED packaging lens technology with the required light output characteristics for street lamps, forming a primary light distribution solution for high-power LEDs.

A. Oblique Rectangular Lens Package for Light Distribution:

The lens is assembled onto the LED bracket, which houses a high-power LED chip. The lens's surface can be coated with an anti-reflection coating, and the cavity between the lens and the chip is filled with high-temperature resistant silicone to minimize light loss due to secondary reflection. Light is refracted directly through the lens. The top surface of this lens is a rectangle with rounded corners, and the rectangular surface is arc-shaped, maintaining a specific angle with the horizontal direction. This design allows for controlled adjustment of the LED chip's light output direction. In comparison to conventional LED lenses, this lens serves a polarizing and anti-reflective function, essentially integrating a secondary optical lens with the primary lens to enhance light extraction. Refer to Figure 7-5 for the primary types of light intensity output characteristic curves.

Figure 7-5 illustrates the LED primary light distribution scheme using oblique rectangular lenses.

Typically, street lights are spaced at a distance about three times the height of the lights. Calculations reveal that the light output angle of the lamp is approximately 140° in the CO/C180 direction, approximately 80° in the C90/C270 direction, with an elevation angle of roughly 10°, which results in satisfactory road lighting. LEDs packaged with oblique rectangular lenses can easily redistribute light for LED street lamps.

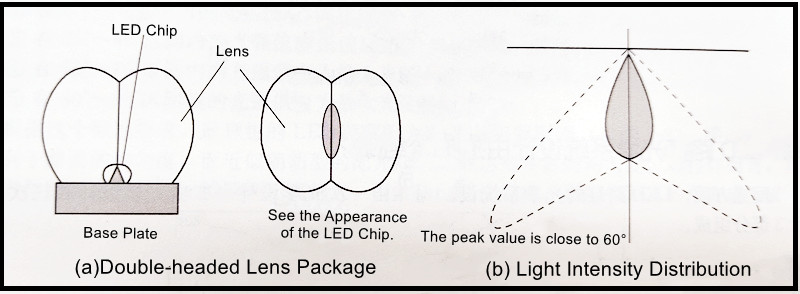

B. Double-Headed Lens Package for Light Distribution:

Figure 7-6(a) presents a schematic diagram of the primary light distribution of an LED packaged with a double-headed lens. Its light output characteristics are modified into a batwing shape, as shown in Figure 7-6(b), which can meet the requirements for road lighting. By redesigning the light distribution for LED street lights, we can achieve the desired road lighting effect.

Figure 7-6 illustrates the LED primary light distribution scheme and the light intensity distribution of double-headed lenses.

② LED Secondary Light Distribution Scheme:

The secondary light distribution solution for LEDs involves using lenses and reflectors to distribute light on existing high-power LEDs. Various secondary light distribution solutions for LEDs are available, and some examples are as follows:

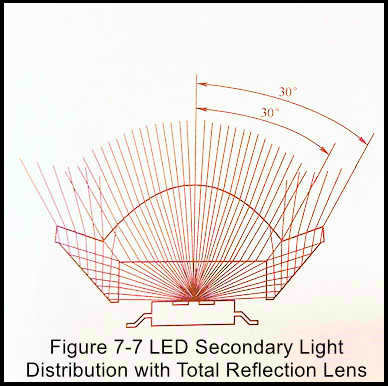

A. LED Secondary Light Distribution with Total Reflection Lens:

Figure 7-7 illustrates the secondary light distribution of a single LED using a total reflection mirror. An axis-symmetric total reflection lens with a plano-convex aspherical lens in the middle uniformly distributes the light emitted by the LED within an angle of ±64° to the optical axis, within a range of ±30°. The remaining light reflected by the side pillars is also concentrated at ±64°, resulting in a uniform light output within a range of ±30°. The far-field distribution of light intensity takes on a batwing shape. By designing the light distribution for street lamps, a common street lamp with a height of 10m can create a uniform rectangular lighting effect measuring 35m in length and 10m in width on the road surface to be illuminated.

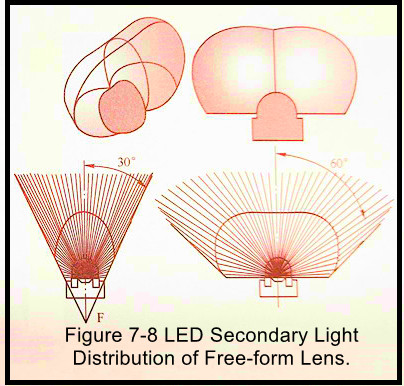

B. LED Secondary Light Distribution with Free-Form Lens:

Figure 7-8 presents a plan for LED secondary light distribution using a free-form lens. The lens's free-form surface is an asymmetric rectangle on the x and y axes. It generates a uniform light distribution of ±60% on the x-axis to meet the lighting requirements in the length direction of the road, and it produces a uniform light distribution of ±30° on the y-axis to achieve an LED batwing-shaped light distribution with a rectangular lighting effect. The light distribution of the lamps only requires a simple superposition of the light output from individual LED units, and it's directly accomplished through LED secondary light distribution to meet the road's lighting requirements. For different roads, you can adjust the number of LEDs and the lamp height as needed, according to specific requirements.

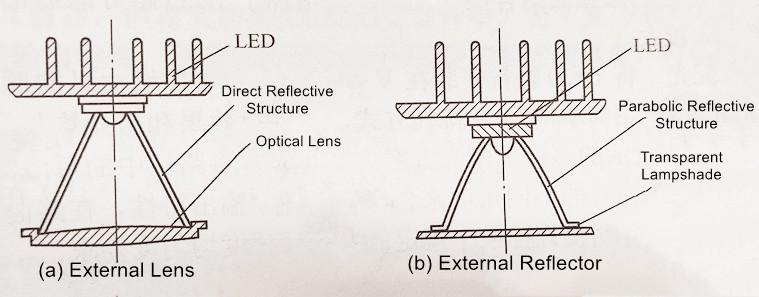

C. LED secondary light distribution with external lens and reflector. Figure 7-9 shows the LED secondary light distribution structure with external lenses and reflectors. As long as the LED is selected in a targeted manner, the appropriate lens is designed, and the curvature of the reflector is correctly selected, the light output of the LED secondary light distribution that meets the requirements can be obtained.

Figure 7-9 LED secondary light distribution structure with external lens and reflector

(1) Planar Light Distribution:

Planar light distribution for LED street lights involves the even arrangement and installation of several LEDs that have undergone primary or secondary light distribution, creating a batwing-shaped light output on a flat surface. Since the size of LEDs can be considered as point light sources relative to the installation height of street lights, typically 8 to 10 meters high, the light distribution achieved by multiple LEDs arranged in a plane is essentially the same as that of a single LED. In the planar light distribution method, the lamp's role is simply to combine the light output of individual LEDs. Usually, this method yields satisfactory road lighting effects without the need for further light distribution adjustments. Planar arrangement is becoming the prevailing trend in LED street lights due to its benefits in terms of heat dissipation performance, processing simplicity, and reliability. Additionally, specialized lenses with unique light distribution patterns have been developed for flat street lights. For example, the Osram Opto Semiconductors' Golden Dragon Oval Plus LED employs a primary resin lens with ideal light distribution performance, providing energy-efficient and highly uniform road lighting without the need for secondary optical components. Several lens manufacturers have successfully created secondary optical lenses for LEDs from Osram Opto Semiconductors, Cree, and Lumiled, allowing LEDs to achieve bat-wing light distribution. Figure 7-10 illustrates an LED street light fixture with a planar arrangement for light distribution.

Figure 7-10 LED street lamps with flat arrangement light distribution

(2) Cylindrical Light Distribution:

The schematic diagram of the light distribution structure for cylindrical lamps is depicted in Figure 7-11. LEDs with a narrow output angle, such as those using total reflection lenses with a range of ±30°, are installed and arranged in a cylindrical arc shape. This arrangement creates a light distribution of approximately 60° in the arc direction. Depending on the lamp's installation height, the elevation angle relative to the horizontal plane, and the distance between lamps, the curvature of the arc and the density of LED arrangement along the arc can be adjusted to achieve lighting effects on the road. This lighting pattern forms an approximate rectangular surface along the longitudinal direction of the road, meeting the relevant requirements of road lighting standards. However, this light distribution scheme does pose certain challenges, primarily in the integration between the heat dissipation plane of a single LED and the arc surface of the installation. This integration issue increases the complexity of manufacturing the LED street light's radiator and housing, and also results in a larger lamp body thickness.

Figure 7-11 Schematic diagram of light distribution structure of cylindrical lamp

(3) Multi-folding Light Distribution:

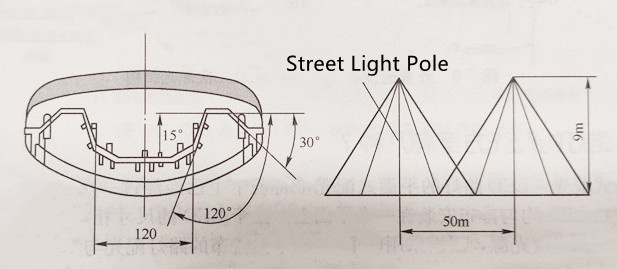

By installing LED components on a V-shaped base, the vertical lighting area can be expanded, and vertical lighting uniformity can be enhanced. However, with a simple V-shaped arrangement, improvements in illumination effectiveness and uniformity are limited. To address this limitation, the multi-folding light distribution scheme depicted in Figure 7-12 can be employed. This approach involves placing groups of high-power LEDs in streetlights on separate planes and merging the light output characteristics from varying relative angles. This results in an approximately rectangular lighting pattern on the road surface, meeting the requirements of road lighting design standards, including specified brightness and illumination uniformity criteria.

Figure 7-12: Schematic diagram illustrating the three-dimensional light distribution structure and the impact of a multi-folding lamp.

(4) Module Zigzag Light Distribution:

The module zigzag light distribution scheme is akin to the multi-fold light distribution approach. In this scheme, the LEDs needed for streetlights are arranged on multiple modules. Each module is inclined at a specific angle and mounted on the same lamp bracket. Through the combination of several modules, a light distribution curve resembling a batwing shape is achieved. The structure of a typical LED street light with a module zigzag light distribution is showcased in Figure 7-13.

Figure 7-13: Illustration of the structure of modular polygonal light distribution LED lamps.

(5) Three-Dimensional Curved Light Distribution:

Figure 7-14 displays a three-dimensional curved light distribution LED street light fixture. The three-dimensional curved light distribution method entails equipping each LED with a secondary optical lens or reflective ring to produce a narrow beam of light distribution. Subsequently, multiple LEDs are arranged on a three-dimensional curved surface to create a comprehensive braided beetle-wing light distribution.

Figure 7-14: Structure of three-dimensional curved light distribution lamps.

(6) Reflector Light Distribution:

In traditional road lighting fixtures, such as high-pressure sodium lamps, the use of reflectors to modify light output characteristics is a commonly employed light distribution method. In LED lighting, owing to the favorable light output direction characteristics of LEDs, some argue for reducing or eliminating the use of reflectors. However, in the design of high-power LED street lights, to fully utilize the peripheral light emitted by LEDs and modify their light output characteristics, a reflector is combined with the light distribution of an individual LED to achieve satisfactory street light output characteristics.

In the design of LED street lights, high-power LEDs emitting light at wide angles are utilized. Each LED is customarily equipped with an asymmetric reflector in the y-axis direction (as depicted in Figure 7-15). This design results in a light distribution curve closely resembling a bat-wing shape, while also reducing light loss due to the inclusion of lenses.

Figure 7-15: Illustration of individually designed asymmetric reflector light distribution.

Using reflector light distribution that aligns with the lighting properties of LEDs is a practical solution. Figure 7-16 portrays an LED street lamp employing reflector light distribution manufactured by a domestic company.

Figure 7-16: Depiction of LED lamps utilizing reflectors for light distribution.

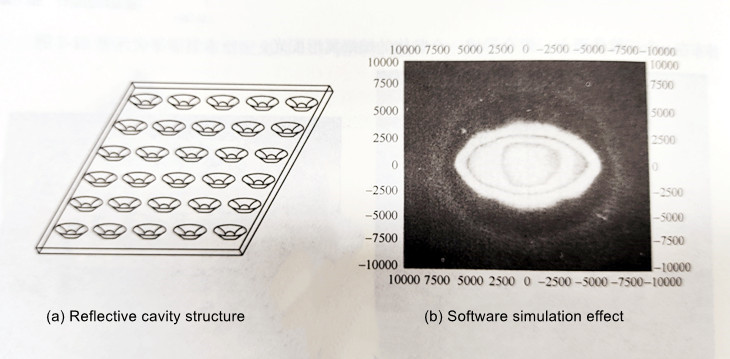

In line with the principle of light reflection, the reflector is fashioned into a light-concentrating groove structure. Each groove corresponds to an LED light source (as seen in Figure 7-17(a)], enhancing light extraction efficiency and effectively controlling light emission angles and light intensity distribution. This, in turn, improves illumination uniformity and road surface brightness. Figure 7-17(b) presents a software-simulated effect.

Figure 7-17: Representation of the reflective cavity structure and software-simulated renderings.

In addition to the aforementioned LED street light light distribution solutions, there are also optical designs in the market that are based on traditional street lights.

LEDER Lighting's 80~120W integrated LED street lights integrate multiple LEDs into a circular area with a specific diameter, ensuring that the light output density in this area closely matches that of high-pressure sodium lamps. To meet light distribution requirements, a lamp reflector is employed through secondary optical design. However, due to this design's incorporation of high-density LEDs in a compact space, it unavoidably impacts the heat dissipation of both the LEDs and the street lights, subsequently affecting their service life.

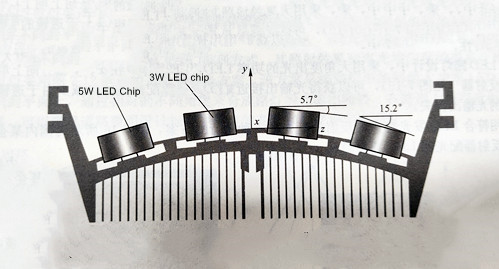

Numerous methods exist to modify light intensity in various directions through LED arrangements. Figure 7-18 illustrates a typical solution where LEDs are positioned on a curved surface with four distinct illumination directions. LEDs situated on the outer sides are of higher power than those in the middle, forming LED street lights comprised of LED modules with varying power combinations. These modules can effectively control the light distribution range through their light guidance. While this approach can achieve better lighting uniformity, it results in a more complex lamp body heat dissipation structure. Additionally, it necessitates the use of LEDs with different power levels and, in some cases, multiple types of lenses, introducing complexity to the LED street light design and increasing costs.

Figure 7-18: Achieving the required light intensity distribution through specific LED arrangements.

In conclusion, the design of efficient LED street lighting is a complex process that requires careful consideration of various factors, including light distribution schemes, optical components, and the specific needs of different road types. LED street lights have revolutionized urban illumination with their energy efficiency and flexibility, offering a range of light distribution solutions to meet the diverse demands of modern cities. As we continue to advance in the field of lighting technology, it is clear that LED street lights will play a crucial role in creating safer, more sustainable, and well-illuminated urban environments for the future. Whether it's the bat-wing distribution, planar arrangement, cylindrical design, or other innovative approaches, the evolution of LED street lighting represents a beacon of progress in urban infrastructure, lighting the way for a brighter and more energy-efficient future.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China