Luminous intensity, referred to as light intensity: refers to the luminous flux emitted by a point light source in a given direction within a unit solid angle, the unit is candela, and the symbol is cd. 1cd=1lm/1sr (sr: steradian unit of solid angle).

For example: a 40W incandescent lamp has a luminous intensity of about 30cd directly below it, and there is a considerable amount of luminous intensity in all directions around the bulb. And above it, due to the cover of the lamp holder, wires, and lamp holders, the luminous intensity upward is almost zero.

Luminous intensity is relevant when dealing with point light sources or when the size of the luminous body is significantly smaller than the distance of irradiation. It indicates the focusing ability of the emitted light in space. Luminous intensity is commonly used to describe the brightness of a light source since it combines both light power and convergence ability. A higher luminous intensity corresponds to a brighter appearance of the light source. Moreover, objects illuminated under the same conditions by a light source with greater luminous intensity will appear brighter.

So what is luminous flux, in layman's terms, luminous flux refers to the total amount of light emitted by the light source, that is, the amount of light passing through, the unit is lumen, and the symbol is Lm. Therefore, the relationship between illuminance, luminous intensity and luminous flux should be: 1lux=1lm/square meter=1cd×sr/square meter.

Of course, this may still be a bit abstract, so let’s illustrate it through a set of calculations:

For example, if there is a 100W incandescent lamp, the total luminous flux emitted by it is 1200Lm (theoretical value, please do not compare it to reality). First, we assume that the luminous flux of this lamp is evenly distributed on a certain hemispherical surface, then the illuminance values at a distance of 1m and 5m from the incandescent lamp can be obtained according to the following steps:

The area of a hemisphere with a radius of 1m is 2π×12=6.28 m2, and the calculation method of the illuminance value at a distance of 1m from the light source is: 1200Lm/6.28 m2=191Lux;

With the same algorithm, the area of a hemisphere with a radius of 5m is: 2π×52=157 m2, and the illuminance value at a distance of 5m from the light source is: 1200Lm/157 m2=7.64Lux.

Simple understanding, that is, using the same light source or lamp for lighting, the farther away from the light source, the less luminous flux and lower illuminance.

In common everyday parlance, when speaking of the efficiency of light sources, we usually mean their luminous efficiency, measured in lumens per watt (lm/W). Another measure is radiated power. The impact of effectiveness and efficiency needs to be considered, discussing the decision-making process that product developers must follow as this affects the efficiency of the overall system.

Calculating functional metrics involves determining the luminous flux of the light source (lm) versus the electrical input power (W). In contrast, the corresponding photometric radiance does not take into account the sensitivity of the human eye, but is a pure efficiency measurement. Electrical input power (W) divided by optical radiant output power (W) yields percent efficiency. The efficiency of an LED depends on many different factors. We will detail some of them in this article.

Generally, the luminous efficacy of incandescent lamps and fluorescent lamps is 15lm/W and 60lm/w respectively, the greater the power of the bulb, the greater the luminous flux. For a high-performance LED device, the luminous efficiency is 20lm/w, and the laboratory level can reach 100lm/W.

In lighting applications, it is often necessary to know that when LEDs are used as lighting sources, it is desirable to know the luminous flux Φ of the surface element irradiated by this light source on a certain point on the receiving surface.

Our understanding of brightness does not need to be so complicated. To put it simply, the human eye observes the light source from one direction. The ratio of the light intensity in this direction to the area of the light source "seen" by the human eye is defined as the brightness of the light source unit, that is, the luminous intensity per unit projected area. Simply put, it means "how bright it looks here", and its unit of measurement is candela per square meter (cd/㎡).

The luminous angle of an LED is an important parameter in LED application products. It refers to the angle at which light is emitted or scattered by the LED. The light-emitting angle, also known as the light scattering angle, is mainly controlled during the production of the diode by incorporating a scattering agent.

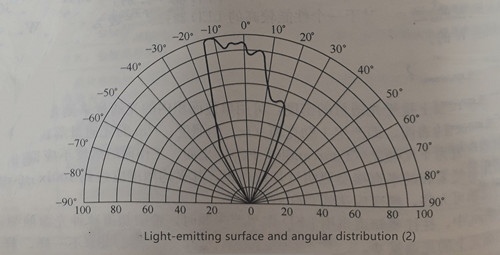

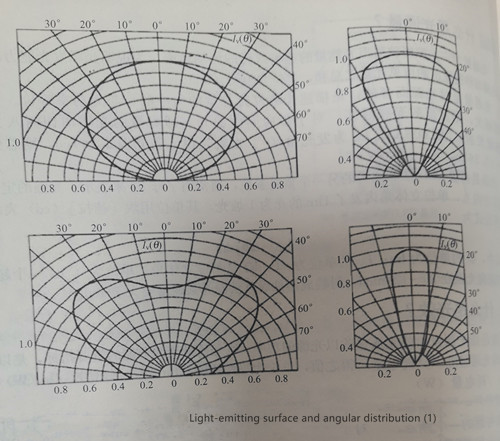

The spatial distribution of LED luminous intensity is often referred to as the light distribution curve, as depicted in Figure 1-1 and Figure 1-2. It is evident that the spatial distribution of LED luminous intensity is not uniform. The radiation characteristics of LEDs depend on the structure of the packaged semiconductor chip and the form of packaging. Packaged LEDs may include internal reflective cups, lenses, scattering agents, and color filter materials.

When the color of light emitted by a light source matches the color radiated by a black body at a specific temperature, that temperature is referred to as the color temperature of the light source. Color temperature is expressed in thermodynamic temperature units, with the unit being Kelvin (K).

As a standard black body is heated, its color gradually changes from dark red to light red, orange, white, and finally to blue. The temperature at which this color change occurs corresponds to the color temperature of the light source.

The color temperature of LEDs generally falls within the range of 4600 to 15000K. This range is higher than that of incandescent lamps and similar to that of fluorescent lamps and HID lamps. Currently, LED products with a color temperature of 2500 to 4600K, which mimic the color of incandescent lamps, are also available on the market. This flexibility in color temperature allows for greater design freedom when using LEDs.

Thereby,Lighting designers can choose from a variety of color temperatures to achieve the desired lighting effect, as flexibility gives lighting designers more control over the mood and aesthetics of their lighting designs.Ultimately leading to a heightened appreciation ation from clients for their customized lighting solutions, particularly when using LED luminaires.My professional lighting customers, do you agree?

7.1 What are the types of color temperature?

Color temperature exhibits the following properties:

①In high latitude areas, the color temperature is higher, and the color you see is bluish.

②In low latitude areas, the color temperature is lower, and the color seen is reddish.

③During the day, the color temperature also changes. When the sun shines obliquely, more energy is absorbed by clouds and air, so the color temperature is lower; when the sun shines directly, less energy is absorbed, so the color temperature is higher.

Table 1-3 illustrates the correlated color temperatures of different light source environments.

Table 1-3: Correlated Color Temperatures of Different Light Source Environments (in Kelvin)

|

Light Source |

Color Temperature Range |

|

Clear Morning Sky |

4400K |

|

Northern Sky |

8000-8500K |

|

Midday Sun in Summer |

5500K |

|

Afternoon Sun in Summer |

4000K |

|

High Pressure Sodium Lamp |

1950-2250K |

|

Candlelight |

2000K |

|

High-Pressure Mercury Lamp |

3450-3750K |

|

Halogen Lamp |

3000K |

|

Cool White Fluorescent Lamp |

4000-5000K |

|

Incandescent Lamp |

2700K |

|

Warm White Fluorescent Lamp |

2500-3000K |

|

LED Street Light |

5500-6000K |

7.2 what is color temperature in lighting?

The color temperature of a light source determines its light color, which in turn affects the ambiance it creates. Light sources with a color temperature below 3300K emit a warm and cozy light, providing a stable atmosphere. In the range of 3000K to 5000K, light sources produce a refreshing light. However, when the color temperature exceeds 5000K, the light tends to feel cold. The combination of different light colors from various light sources contributes to creating the optimal environment. Table 1-4 presents the correlation between color temperature and human perception.

Table 1-4: Color Temperature and Human Perception

|

Color Temperature Range |

Light Color Type |

Human Perception |

Examples of Light Sources |

Suitable Locations |

|

>5000K |

Cool (Bluish) |

Close to natural light, bright feel |

Daylight fluorescent lamps, bluish space |

libraries reading area

|

|

3000~5000K |

Intermediate (White) |

Soft light, pleasant, comfortable, serene feel |

Sunlight, cool white fluorescent lamps |

Stores, hospitals, offices, hotels, restaurants, waiting rooms, etc. |

|

<3300K |

Warm (Whitish with a hint of red) |

Warm, stable, healthy, cozy feel |

Incandescent lamps, warm white fluorescent lamps |

Residential homes, dormitories, hospitals, hotels, or places with lower temperatures |

When our lighting team created the design plan, we took into consideration the use of light sources with color temperatures exceeding 4000K in areas with high temperatures, and light sources with color temperatures below 4000K in areas with low temperatures. It is important to note that low brightness levels under high color temperature light sources can create a cold atmosphere, while excessive brightness from low temperature light sources may lead to a stuffy feeling. By incorporating two light sources with contrasting colors in the same space, we can achieve layered effects. Furthermore, significant contrast in light colors allows us to achieve both the desired light color and appropriate brightness levels simultaneously.Did your team take these factors into account when creating the design plan?

The color rendering ability of a light source to an object is called color rendering, and is usually measured by a color rendering index. Color rendering index of incandescent color LED

The color rendering index of general white LEDs is 60-80. It is roughly the same as fluorescent lamps. Recently developed short-wavelength LEDs combined with RGR tricolor phosphors have an average color rendering index of 90.

Due to the difference in the composition of the spectrum in the light, the color rendering of the lamp may be different even if the light color is the same.

The color rendering index of LED has nothing to do with the power, but it is related to the performance of the chip used. The color rendering index with good chip performance means that in addition, the LED packaging technology also has an impact on the color rendering index. The color rendering index of LEDs with better packaging technology can reach 90.

(1) Faithful color rendering.

Faithful color rendering can accurately express the original color of the material, and it is necessary to use a light source with a high color rendering index. When the value is close to 100, the color rendering performance is the best.

(2) Effect color development.

To clearly emphasize a specific color and express a beautiful life, you can use the additive color method to enhance color rendering

Effect.

① Irradiation with a low color temperature light source can make the red color more vivid.

② Illumination with medium color temperature light source can make the blue feel cool.

③Irradiation with high color temperature light source can make the object have a cold feeling.

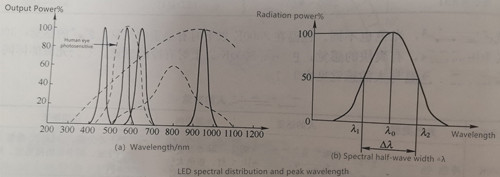

In general, LEDs emit optical radiation composed of multiple wavelengths of light, and the proportions of these wavelengths can vary. The spectral distribution of an LED is determined by the type and properties of the compound semiconductor used in its fabrication, as well as the PN structure (outer layer thickness, doping impurities), and is unrelated to the geometry and packaging method of the device. Figure 1-3 illustrates the spectral response curves of several LEDs fabricated using non-compound semiconductor doping.

It's important to note that the light emitted by an LED is not limited to a single wavelength. Figure 1-3 demonstrates that the peak wavelength, at which the luminous intensity of a certain wavelength (λo) emitted by the LED is the highest, can be observed.

How many thermal performance parameters does LED have? The typical answer is that there are only two parameters: the first junction temperature is the highest temperature of the actual semiconductor chip (wafer, bare chip) in the electronic device. Usually we say that the maximum junction temperature specifies the data of a component and calculates the thermal resistance between the shell and the environment under the condition of given power consumption. The second thermal resistance means that after the LED is lit, when the heat conduction is stable, the chip surface dissipates every 1W, and the temperature difference between the temperature of the PN junction and the branch of the connection or the heat dissipation substrate is the thermal resistance Rth of the LED. The thermal resistance value is generally represented by θ or R, where Tj is the temperature at the junction position, Tx is the temperature at which heat is transferred to a certain point, and P is the input heating power.

①Junction temperature and maximum junction temperature. The PN junction temperature of the LED is referred to as crystallization, and the maximum junction temperature of the LED refers to the highest critical temperature that the PN junction of the LED can withstand. The highest junction temperature of the LED is related to the semiconductor material used in the LED, the packaging structure, and the packaging material. This temperature is usually 120~150C. Once the PN junction temperature of the LED exceeds the maximum junction temperature, it will lead to permanent failure of the LED.

②The relationship between the working temperature of an LED lamp and the thermal resistance of the lamp chip is significant in determining the LED's performance and longevity.

Firstly, we need to clarify the thermal resistance, typically measured from the PN junction to the pad foot. The LED specification usually includes the maximum temperature that the PN junction can tolerate (usually around 120-150 degrees Celsius). Once the finished product is assembled, we can only measure the temperature of the pad foot. Using thermal resistance, we can calculate the temperature of the PN junction. For instance, if the LED is powered at 1W, and the temperature of the pad foot is 70 degrees Celsius, then the temperature of the PN junction can be calculated as (1W * 13°/W) + 70 degrees. It is crucial to ensure that the temperature remains within an acceptable range, as exceeding or getting close to the maximum temperature could result in significant LED light decay.

Secondly, the temperature of the cooling case is calculated based on the thermal resistance between the pad and the case. This involves considering factors such as the thermal resistance of the aluminum substrate and the internal cavity of the heat sink. As a finished product, it is essential to conduct an aging test to evaluate the temperature of critical components, such as the casing, power supply, lamp board, and LED pad feet.

One approach to ensure proper LED performance is to manufacture the finished product and monitor the temperature of the lamp bead foot. Once the lamp reaches a stable heat level, it is essential for the temperature of the lamp bead to remain below 65 degrees Celsius when the ambient temperature is 30 degrees Celsius. This approach assumes a thermal resistance of 13°/W, meaning that the PN junction temperature will be 13 degrees higher than the temperature of the lamp feet when the lamp's working temperature stabilizes.

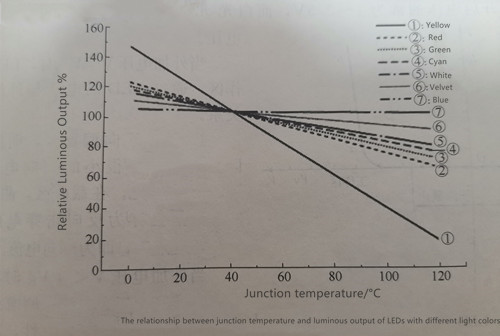

For example, LEDs experience a decrease in lumen output as temperature increases, as shown in Figure 1-4. Additionally, the forward voltage drop of an LED will decrease with an increase in junction temperature.

Like traditional light sources, LEDs generate electrical heat when they are in operation. Under the action of an external electric field, a large number of electrons and holes recombine in LEDs. Except for a small part of the energy released in the form of light energy, most of the other energy is released in the form of non-radiation, which causes the vibration of the semiconductor lattice and generates heat. Cause LED junction temperature rise. As the LED chip junction temperature rises, microscopic parameters such as electron and hole concentrations, forbidden bandwidth, and electron mobility inside the PN junction will change, thereby affecting the photoelectric parameters of the LED. For example, LEDs decrease lumen output as temperature increases, as shown in Figure 1-4. Another example is that the forward voltage drop of LED will decrease with the increase of junction temperature.

In order to ensure that the temperature of the PN junction of the LED is within a certain range, it is extremely important to solve the heat dissipation problem of the LED. It is a key technology related to the development of semiconductor lighting.We have implemented a unique heat dissipation design in our LED lamps. If you are interested in learning more, please feel free to contact us.

LED light decay refers to the decrease in luminous intensity over time after the LED has been illuminated. Generally, Our LED manufacturer conduct tests in laboratory conditions at a room temperature of 25°C. They continuously illuminate the LED with a 20mA DC current for 1000 hours and compare the luminous intensity before and after the test to measure light decay.

The light decay of LEDs is primarily influenced by two factors. Firstly, it can be attributed to quality issues with the LED product itself. If the LED chip used is of poor quality, the brightness may decay rapidly. Additionally, manufacturing defects can lead to ineffective heat dissipation from the LED chip, resulting in high chip temperatures and exacerbating the decay process. The second factor relates to the conditions under which LEDs are used. LEDs are typically driven by a constant current, but if driven by voltage instead, it can cause increased attenuation. Moreover, driving currents exceeding the rated conditions can also contribute to accelerated LED decay.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China