LED street lights are crucial for urban development, yet the market is currently rife with varying prices and inconsistent quality. In the Chinese market, manufacturers often lack patent awareness and fail to innovate, triggering price wars that drive down costs in materials and processes. Consequently, the quality of LED street lamps suffers, leading to issues like dimming over time.

Replacing LED street lights is arduous due to their complex internal components. Aside from the light source (chip), damage to other parts can also result in the chip failing to light up. Identifying the cause of LED street light damage on-site is challenging, requiring removal and transportation back to the factory for thorough testing. This complexity, coupled with the difficulty of installing and maintaining high-altitude outdoor devices like LED street lights, significantly increases maintenance costs for street light managers.

LEDER Lighting Laboratory specializes in testing LED street light materials. We conduct comprehensive evaluations covering the entire lamp material, identifying product defects, performing lamp sulfur emission tests, assessing photoelectric and heat dissipation performance, and scrutinizing assembly and craftsmanship. Our assessments swiftly resolve LED street light acceptance issues, benefiting hundreds of government procurement agencies and preventing potential losses for you. We ensure a quick and accurate assessment of LED street light quality, providing solutions to avoid unnecessary expenses.

1. Configure virtual mark

The popularity of LED street lights is also accompanied by a decrease in price and profit. The fierce competition has also led to many businesses beginning to cut corners and falsely mark product parameters. This is also caused by customers repeatedly comparing prices and demanding low prices. It is also caused by some manufacturers. Related to practice.

2. Counterfeit chips

The core of LED lamps is the chip, which directly determines the performance of the lamp! However, some unscrupulous businesses take advantage of customers' unprofessionalism and use low-priced chips based on cost considerations, causing customers to buy low-quality products at high unit prices, causing direct economic losses and causing serious quality hazards to LED lamps.

3. Copper wire pretending to be gold wire

Many LED manufacturers are trying to develop products such as copper alloys, gold-coated silver alloy wires, and silver alloy wires to replace expensive gold wires. While these alternatives are superior to gold wire in some properties, they are far less chemically stable. For example, silver wire and gold-coated silver alloy wire are susceptible to sulfur/chlorine/bromide corrosion, and copper wire is prone to oxidation and sulfurization. For encapsulated silicone similar to water-absorbent and breathable sponges, these alternatives make the bonding wire more susceptible to chemical corrosion, reduce the reliability of the light source, and make the LED lamp beads more likely to break and die after being used for a long time.

4. The design of the street light distribution system is unreasonable

In terms of optical design, if the light distribution system of the street lamp is not designed properly, the lighting effect will not be ideal. During the test, problems such as "bright under the light", "dark under the light", "zebra crossing", "uneven illumination", and "yellow circles" will appear.

5. Poor heat dissipation design

In terms of heat dissipation design, every time the PN junction temperature of the LED chip increases by 10 degrees, the life of the semiconductor device will decrease exponentially. Due to the high brightness requirements of LED street lights, the use environment is relatively harsh. If the heat dissipation is not solved properly, it will quickly cause the LED to age and reduce its stability.

6.Power failure

In terms of driving power supply, if the power supply is faulty, during the test and inspection process, phenomena such as "the entire lamp goes out", "partial damage", "individual LED lamp beads are dead", and "the entire lamp flickers and lights up falsely" will occur.

7.Safety failure

Safety issues also deserve serious attention: the street light power supply has no leakage protection; the quality of the street light ballast is shoddy; the circuit breaker has not been subjected to sensitivity calibration tests, and the rated tripping current is too large; the metal sheath of the cable is used as the PE main line The process is complex and the reliability is low; the IP waterproof and dustproof level is too low.

8. Lamps contain substances harmful to the light source

Blackening of LED light sources is a problem that major LED companies often encounter. Most materials in lamps need to be checked for substances that affect the life of the light source.

The emergence of the above problems will have a greater impact on the performance of LED street lights, and may even cause premature failure of LED street lights. In response to the above problems, LEDER Lighting has mature testing methods that can fully identify the advantages and disadvantages of LED street lights from raw materials and provide acceptance recommendations to avoid subsequent losses.

① Completeness of relevant certifications.

② Comprehensive photoelectric performance testing of lamps.

③ Evaluation of the core light source quality in lamps.

④ Assessment of the lamps' heat dissipation performance.

⑤ Presence of harmful chemicals to the light source in the lamps.

⑥ Identification of power supply quality.

⑦ Source identification of the chip used.

⑧ Inspection of the lamp's appearance and structure.

⑨ Waterproof testing.

① Verification of Complete Lighting Fixture Certifications:

Validation according to bidding requirements.

② Rapid Quality Assessment of LED Street Lights:

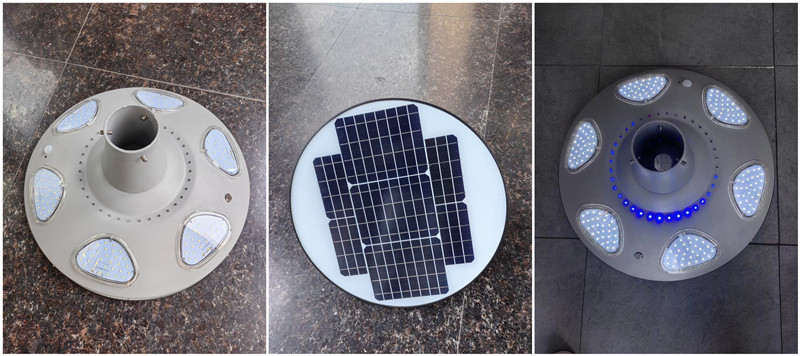

LED streetlights consist primarily of light sources, power supplies, and radiators. We initiate assessments from a material perspective, swiftly evaluating LED lamp raw materials and processes to ascertain their quality.

A. Comprehensive Photoelectric Performance Testing:

* Total luminous flux

* Luminous efficiency

* Light intensity distribution

* Correlated color temperature (CCT)

* Color rendering index (CRI)

* Chromaticity coordinates or color degree coordinates

* Input AC or DC voltage

* Input AC or DC current

* Input power DC or AC

* Input voltage frequency

* Power factor

B. LED lamp core light source quality assessment involves evaluating various aspects of the LED light source lamp beads:

* Assessment of lens processing, packaging glue type, identification of contaminants, bubbles, and airtightness evaluation.

* Evaluation of the phosphor coating process, including phosphor particle size, distribution, composition, agglomeration, and sedimentation.

* Examination of chip manufacturing process, microstructure measurement of a chip pattern, defect detection, identification of contaminants, leakage, and damage assessment.

* Assessment of wire bonding process, observation of first and second welding morphology, arc height and diameter measurements, and identification of lead composition.

* Evaluation of the die-bonding process, checking for holes or delamination in the die-solid layer, composition, and thickness measurement of the die-solid layer.

* Assessment of the stent coating process, including stent composition, coating composition, thickness, and stent airtightness.

C. As a new form of energy-efficient lighting, LEDs only convert 30-40% of electrical energy into light during operation, with the remaining transformed into heat energy. The lifespan and quality of LED lamps are closely tied to temperature. The temperature of the lamp beads, shell, and heat dissipation directly influences the uniformity and lifespan of LED lighting.

* Our evaluation of LED lamp heat dissipation involves:

** Assessing the design for heat dissipation in LED lamps.

** Checking for excessive temperatures in each component after the lamp reaches thermal equilibrium.

** Inspecting the heat dissipation materials used in LEDs to ascertain if they possess high specific heat and thermal conductivity.

D. Are harmful substances present in LED lamps affecting their light source?

LED light sources are vulnerable to sulfur, with over 50% of failures stemming from sulfur and bromine chlorination in the silver coating of lamp beads. When this chlorination reaction occurs within the LED light source, the product's functional area darkens, luminous flux diminishes, and significant color temperature drifts can happen. This can lead to leakage during use. In severe cases, complete corrosion of the silver layer and exposure of the copper layer may occur, resulting in gold ball detachment and dead lights.

LED lamps contain over fifty different raw materials, some of which may contain sulfur, chlorine, and bromine. In enclosed, high-temperature environments, these elements can volatilize into gases, corroding LED light sources. Our assessment of sulfur emissions in LED lamps is a crucial report ensuring the stable quality of these lamps.

E. The LED driving power supply plays a vital role in converting AC mains power into suitable DC power for LEDs. When selecting and designing such a power supply, factors like reliability, efficiency, power factor, driving mode, surge protection, temperature feedback protection, and considerations for outdoor use—such as waterproofing, moisture resistance, and aging resistance in the outer shell—must be taken into account. This ensures that the power supply's lifespan matches that of the LED.

Our identification testing covers several key aspects:

* Power supply output parameters: voltage and current.

* Verification of constant current output characteristics, assessing whether it operates in a pure constant current mode or a constant current and constant voltage mode.

* Presence of separate overcurrent, short circuit, and open-circuit protections.

* Detection of power leakage: The shell should remain non-electrified when powered on.

* Measurement of ripple voltage: Lower peak values indicate better performance, with the absence of ripple voltage being optimal.

* Stroboscopic evaluation: Ensuring no flickering occurs after LED street lights are activated.

* Assessment of power-on output voltage/current: Large fluctuations in output voltage/current upon activation are not ideal.

* Compliance with relevant surge standards, such as IEC61000-4-5.

F.Chip source identification

The LEDER Lighting R&D team possesses an extensive LED chip database, encompassing chips from various domestic and international manufacturers. This database is comprehensive, accurate, and regularly updated. By conducting searches and matching processes within this database, we can confirm chip models and their manufacturers. This aids lighting customers in enhancing their quality control procedures and efficiency.

G. The specifications in tender documents outline the exterior materials for lamps and lanterns, which we meticulously review. Our inspection involves several key aspects:

* Appearance assessment: Ensuring uniform paint color without pores, cracks, or impurities. The coating must tightly adhere to the base material. Each component's casing in the LED lamp should have a smooth, flat surface without scratches, wounds, cracks, or deformations.

* Dimensional inspection: Confirming that the overall dimensions align with the provided drawings.

* Material examination: Verifying that the materials used and the structural design of each lamp component adhere to the drawing specifications.

* Assembly evaluation: Checking that surface screws are properly tightened, edges are free of burrs and sharp edges, and connections are secure without any looseness.

H. Waterproof detection

LED street lights serve as outdoor illumination for areas spanning a few meters to over ten meters. Given the challenging nature of replacing and repairing these lights, they require excellent waterproof and dustproof capabilities. Consequently, the waterproofing and dustproofing levels of street lights hold significant importance.

Based on the comprehensive information provided regarding LED street light quality, it's clear that ensuring top-notch quality is pivotal for long-term performance and reliability. LEDER Lighting stands out for its meticulous approach to maintaining quality at its core, ensuring a warranty that truly protects customers' investments.

LED street lights, crucial for urban settings, often face various quality challenges, ranging from substandard materials to design flaws. LEDER Lighting's commitment to addressing these challenges involves thorough testing, scrutiny, and identification of potential issues from raw materials to assembly, culminating in comprehensive solutions for optimal performance.

Quality concerns with LED street lights are diverse, encompassing issues like inadequate waterproofing, counterfeit chip usage, subpar heat dissipation, and compromised driving power supplies. LEDER Lighting not only identifies these issues but also provides effective solutions to prevent subsequent losses and ensure long-term reliability.

Their in-depth assessment covers critical aspects: evaluating light source quality, assessing heat dissipation, detecting harmful substances, confirming power supply reliability, and verifying chip sources, among others. Furthermore, LEDER Lighting emphasizes adherence to tender document specifications, ensuring meticulous inspections of appearance, structure, and waterproofing to meet stringent quality standards.

For customers seeking reliable LED street light suppliers, LEDER Lighting emerges as a standout choice. Their commitment to maintaining quality at every stage of production ensures the delivery of unmatched value, safeguarding customers' investments and guaranteeing real warranty coverage. Contacting LEDER Lighting promises unexpected value, backed by their steadfast dedication to quality assurance and customer satisfaction.

Contact: Mr. Otis

Phone: +8615815758133

Tel: +8615815758133

Email: Hello@lederlighting.com

Add: No. 1 Gaoxin West Road,High-tech Zone, Jiangmen, Guangdong, China